Hello, I’m the CEO of Autojare, and today I’m excited to help you understand the importance of L-type couplings and how to choose the best one for your equipment. Whether you are working in manufacturing, agriculture, or any other industry that relies on machinery, selecting the right coupling is critical for the performance and longevity of your equipment.

At Autojare, we specialize in manufacturing high-quality L-jaw couplings. With over 15 years of industry experience, we understand the value of providing durable, reliable, and affordable couplings. In this article, I’ll break down the key things you need to know to make an informed decision, ensuring that your equipment runs smoothly and efficiently.

What Are L-Type Couplings?

L-type couplings are mechanical components that connect two shafts together, transmitting rotational power and motion between them. They are essential for ensuring that machines operate in harmony, with minimal vibration or misalignment. These couplings are often used in motors, gearboxes, conveyors, and many other industrial applications.

The “L” in L-type refers to the jaw design, which includes two hubs and an elastomer insert (usually made from materials like NBR) that fits between them. This design helps reduce vibrations, misalignments, and wear, making L-jaw couplings an ideal choice for heavy-duty applications.

L-type couplings come in different sizes and configurations, with each being suited to specific industrial applications. However, no matter the application, they all have one thing in common: they provide a reliable solution to maintain the smooth operation of machinery.

Key Features of a Quality L-Jaw Coupling

When choosing a coupling, it’s important to consider the key features that will affect its performance and durability. Here are the most important aspects to keep in mind:

- Material Quality: High-quality materials like HT250 steel are crucial for ensuring strength, resistance to wear, and long-term performance. Cheap or inferior materials will fail sooner, costing you more in the long run. At Autojare, our couplings are made with top-notch HT250 steel to guarantee superior strength and durability.

- Elastomer Inserts: The elastomer insert absorbs shocks and vibrations, protecting your equipment. The material’s quality and design are essential for ensuring smooth performance. We use NBR inserts, known for their high resistance to oils and chemicals, to enhance the coupling’s reliability and longevity.

- Torque Capacity: It’s important to match the coupling’s torque capacity with your equipment’s needs. L-type couplings can handle a wide range of torque loads, from light to heavy-duty applications. By selecting the right coupling for the job, you ensure maximum performance and prevent breakdowns.

- Corrosion Resistance: Depending on your working environment, corrosion resistance can be an important factor. Whether exposed to chemicals, heat, or moisture, a high-quality L-jaw coupling will offer better protection against corrosion, extending its lifespan.

- Compatibility: One of the major advantages of L-jaw couplings is their compatibility with other coupling brands like Lovejoy, Martin, and Browning. This makes it easier to replace and maintain machinery without needing a complete overhaul of your system.

These features combined make L-type couplings a versatile and reliable solution for a variety of industries, including automotive, agriculture, and manufacturing.

How to Choose the Right L-Jaw Coupling for Your Equipment

Selecting the right coupling for your equipment can be tricky, but I’ve broken it down into five key considerations to help you make an informed decision.

1. Size and Fitment

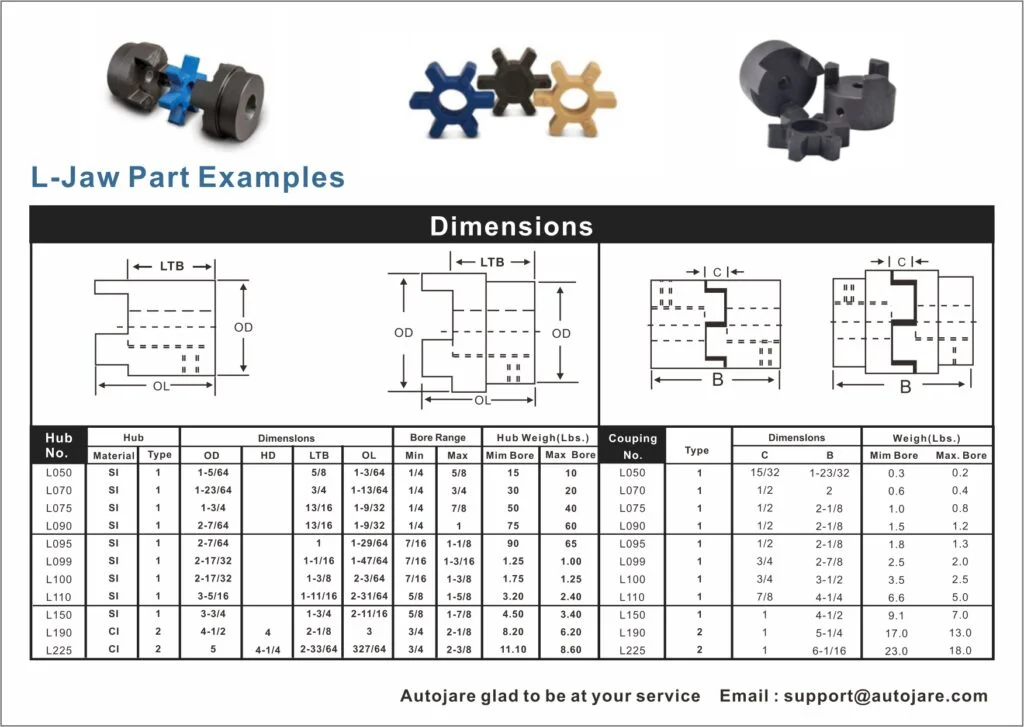

The first thing you need to consider is the size of the coupling. You’ll need to match the coupling’s bore size to the shafts that will be connected. In our L-jaw couplings at Autojare, we offer models like L075, L090, L095, L100 and L110 which cater to a wide range of sizes.

If the coupling doesn’t fit properly, it can cause misalignment, leading to premature wear and tear on both the coupling and the machinery. Always double-check the dimensions and make sure the coupling is compatible with your equipment before making a purchase.

2. Torque Requirements

Each application has specific torque requirements, and selecting a coupling with the right torque rating is crucial. Under-sizing a coupling can lead to premature failure, while oversizing may result in unnecessary expenses. Be sure to know the torque ratings for your equipment, and select a coupling that meets or exceeds these requirements.

3. Load and Speed Considerations

Another important factor is the load and speed at which your equipment operates. High-speed machines or those that experience varying loads require couplings that can handle fluctuating stresses. You’ll want to make sure the coupling you choose can perform effectively under the expected load and speed.

4. Operating Environment

Will your machinery be operating in extreme conditions? Environments with high temperatures, exposure to moisture, chemicals, or dust may require a coupling designed for such conditions. A coupling with superior resistance to these elements will ensure a longer service life and fewer repairs.

5. Ease of Maintenance and Replacement

Maintenance and ease of replacement are also key considerations. High-quality L-jaw couplings are designed for easy installation and maintenance. When selecting a coupling, ensure it is easy to replace or service if needed. This reduces downtime and helps keep your equipment running smoothly.

Why Choose Autojare Couplings?

When it comes to purchasing L-jaw couplings, you want to choose a reliable supplier that offers high-quality products and excellent customer service. Here at Autojare, we are dedicated to producing the best L-jaw couplings in the industry. Here are a few reasons why our couplings stand out:

- High-Quality Materials: Our couplings are made from HT250 steel, ensuring that they are both strong and resistant to wear and corrosion.

- Wide Compatibility: Our L-jaw couplings are compatible with leading brands like Lovejoy, Martin, and Browning, making replacements and upgrades seamless.

- Fast Shipping: We understand the importance of minimizing downtime. That’s why we offer fast shipping worldwide, including the USA, Canada, Europe, and Australia.

- Expertise and Support: With over 15 years of experience, we have the expertise to guide you through the selection process and offer ongoing support to ensure you get the most out of our products.

Whether you’re replacing an old coupling or outfitting new equipment, we provide you with the best options available, ensuring that your machinery runs smoothly, efficiently, and with minimal maintenance.

Conclusion

Choosing the right L-jaw coupling for your equipment is crucial for ensuring smooth operations and long-term performance. By considering factors like size, torque, load, environment, and ease of maintenance, you can make an informed decision that benefits both your equipment and your business.

At Autojare, we’re committed to providing high-quality, durable couplings that meet your specific needs. If you’re looking for a reliable coupling supplier with fast shipping and top-notch customer support, look no further than Autojare.

Feel free to browse our catalog or contact us directly to request a quote today. Let us help you keep your equipment running at its best!

| NBR | SKU | SIZE | Product Link |

|---|---|---|---|

| L075 | LZQ-001 | 1/2” to 3/4” L075 | [Insert Link] |

| L075 | LZQ-002 | 1/2” to 7/8” L075 | [Insert Link] |

| L075 | LZQ-004 | 1/2” to 5/8” L075 | [Insert Link] |

| L075 | LZQ-011 | 3/4” to 3/4” L075 | [Insert Link] |

| L075 | LZQ-012 | 1/2” to 1” L075 | [Insert Link] |

| L075 | LZQ-013 | 5/8” to 5/8” L075 | [Insert Link] |

| L075 | LZQ-014 | 5/8” to 3/4” L075 | [Insert Link] |

| L090 | LZQ-003 | 1/2” to 3/4” L090 | [Insert Link] |

| L090 | LZQ-018 | 1/2” to 1” L090 | [Insert Link] |

| L090 | LZQ-019 | 3/4” to 1” L090 | [Insert Link] |

| L090 | LZQ-020 | 1/2” to 7/8” L090 | [Insert Link] |

| L095 | LZQ-006 | 1/2” to 1” L095 | [Insert Link] |

| L095 | LZQ-007 | 1/2” to 3/4” L095 | [Insert Link] |

| L095 | LZQ-015 | 5/8” to 1” L095 | [Insert Link] |

| L095 | LZQ-016 | 1/2” to 7/8” L095 | [Insert Link] |

| L095 | LZQ-017 | 3/4” to 3/4” L095 | [Insert Link] |

| L100 | LZQ-021 | 3/4” to 1” L100 | [Insert Link] |

| L100 | LZQ-022 | 3/4” to 1-1/4” L100 | [Insert Link] |

| L100 | LZQ-023 | 3/4” to 1-1/8” L100 | [Insert Link] |

| L110 | LZQ-024 | 1” to 1-1/2” L110 | [Insert Link] |

| L110 | LZQ-025 | 1” to 1-3/8” L110 | [Insert Link] |