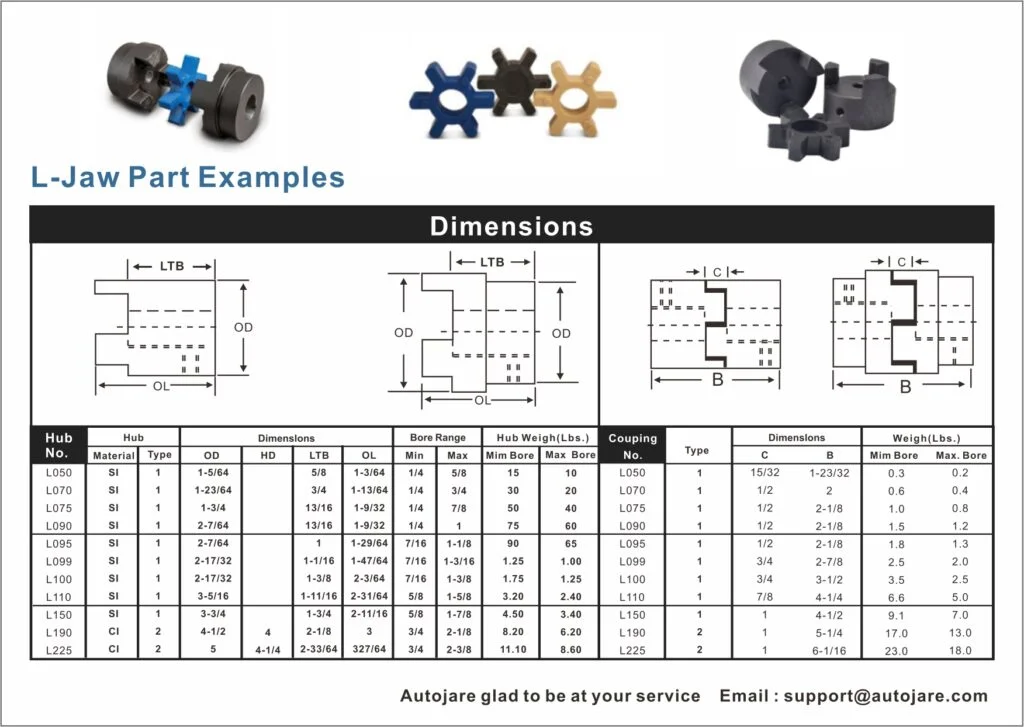

As the CEO of Autojare, specializing in L-Jaw Coupling Sets, I often interact with clients concerned about the lifespan and reliability of our products. A common point of discussion is the maintenance schedule, particularly the frequency of replacing the elements known as ‘spiders’ within these couplings. Ensuring our products operate efficiently over their lifespan is not just a commitment but a cornerstone of our business model.

The replacement schedule for the spiders in our L-Jaw Couplings is not only simple but designed to be cost-effective, ensuring minimal downtime and maximum efficiency for our customers. Knowing when to replace a spider is crucial for maintaining the performance and longevity of the coupling system.

Understanding the Role of Spiders in L-Jaw Couplings

Spiders in an L-Jaw Coupling serve as a flexible element that accommodates misalignments and dampens vibrations between the shafts connected by the coupling. The health of the spider directly affects the coupling’s performance and the machinery’s overall efficiency.

Due to their critical role, these spiders endure a significant amount of mechanical stress, wear, and tear. Regular inspections and timely replacements are vital to avoid mechanical failures and costly downtimes.

Recommended Replacement Schedule

The replacement schedule for spiders can vary based on several factors, including the operational environment, the load on the coupling, and the operational hours. Below is a general guideline that we recommend at Autojare, which is based on typical conditions:

| Operating Condition | Recommended Inspection | Recommended Replacement |

|---|---|---|

| Normal operating conditions | Every 12 months | Every 3-5 years |

| Heavy-duty operations | Every 6 months | Every 2-3 years |

| Extreme conditions | Every 3 months | Annually |

These recommendations ensure that each coupling operates within its best performance parameters, minimizing the risk of unexpected breakdowns and maintenance costs.

Signs That Spiders Need Replacement

It’s important to recognize the signs that indicate when a spider is nearing the end of its useful life. Here are some symptoms to watch for:

- Increased vibration or noise: This could indicate that the spider has begun to degrade.

- Misalignment or excessive movement: Worn spiders may not hold the coupling alignment as effectively.

- Visible wear or degradation: Any visible cracks, hardening, or crumbling of the spider material is a clear sign that it needs to be replaced immediately.

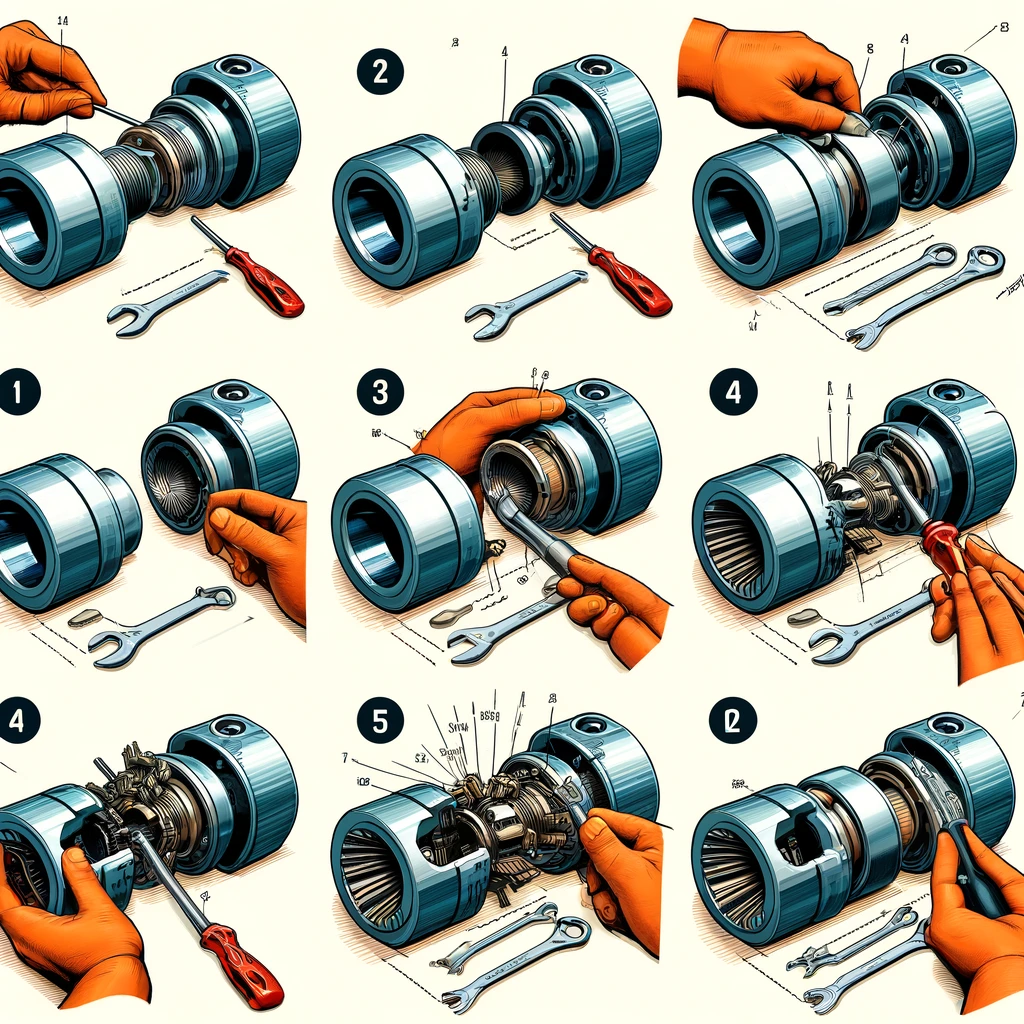

Replacement Process

Replacing a spider in an L-Jaw Coupling is designed to be a straightforward process that can be performed on-site with basic tools. This reduces the need for specialized services and allows our clients to manage their maintenance schedules effectively.

- Disconnect and secure the machinery to ensure safety.

- Remove the cover or guard of the coupling to access the spider.

- Inspect and remove the old spider, taking note of any wear or misalignment.

- Install the new spider, ensuring it fits securely.

- Reassemble the coupling and guard, then test the machine to ensure smooth operation.

Conclusion

At Autojare, we understand that the durability of the components like the L-Jaw Coupling spiders directly impacts our customers’ operational efficiency. By following the recommended replacement schedules and understanding the signs of wear, our customers can greatly enhance the reliability and longevity of their machinery. For further assistance or to purchase replacement spiders, please contact our customer support team or visit our website.