In the world of mechanical components, versatility is not just an advantage; it’s a necessity. As the CEO of Autojare, a brand renowned for our commitment to quality and efficiency in producing L-Jaw Coupling Sets, I often encounter queries about the adaptability of our products. One common question is whether our coupling sets can be used in both horizontal and vertical applications.

To directly address this query: yes, L-Jaw Coupling Sets designed by Autojare are indeed capable of functioning efficiently in both horizontal and vertical alignments. This flexibility allows them to be employed in various machinery and applications across multiple industries.

Continuing on this topic, it’s essential to understand why such versatility is crucial. In industries ranging from manufacturing to energy, equipment often needs to adapt to different spatial configurations to meet specific operational requirements.

Why is versatility important in coupling applications?

In any industrial setting, space constraints and design requirements often dictate the configuration of machinery. Couplings that can operate in both orientations offer a critical solution, simplifying the design process and reducing the need for additional components. This adaptability not only saves on cost but also on installation time and maintenance.

How do L-Jaw Couplings achieve this adaptability?

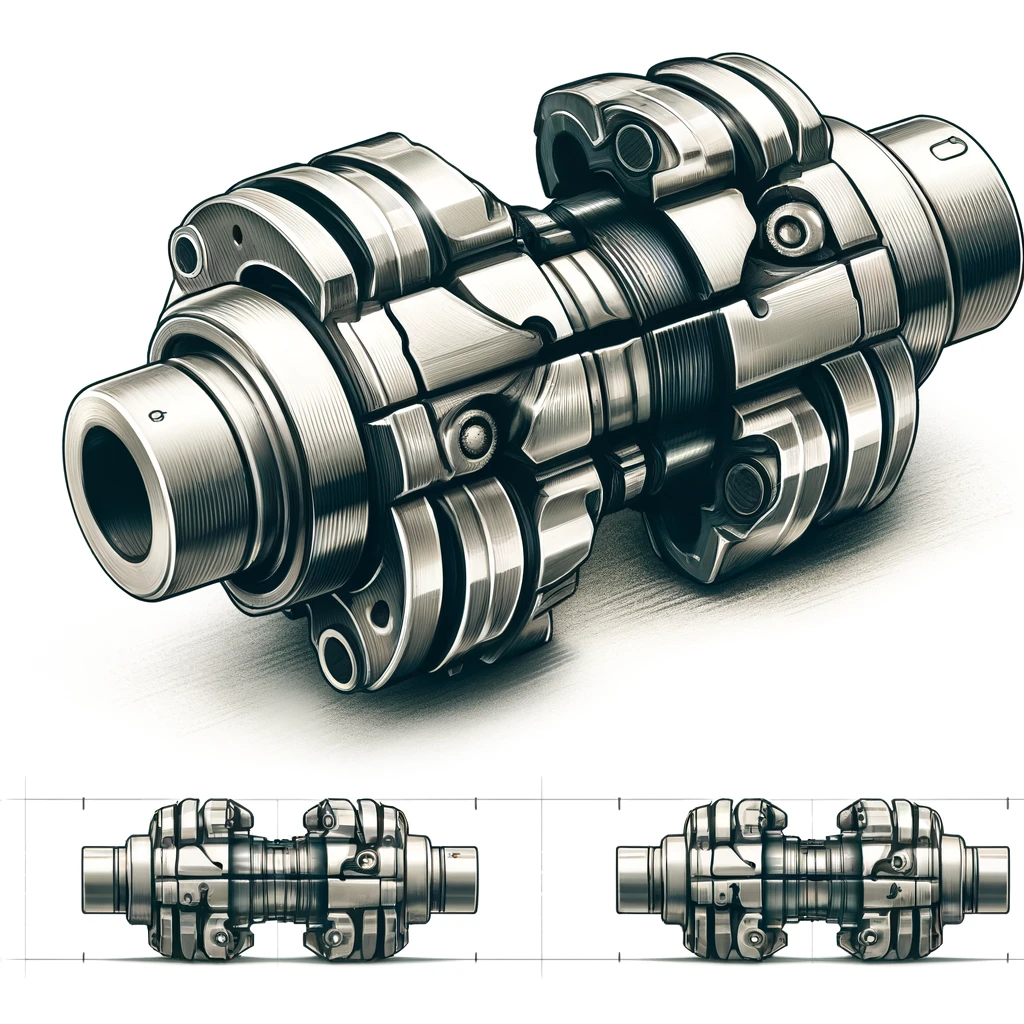

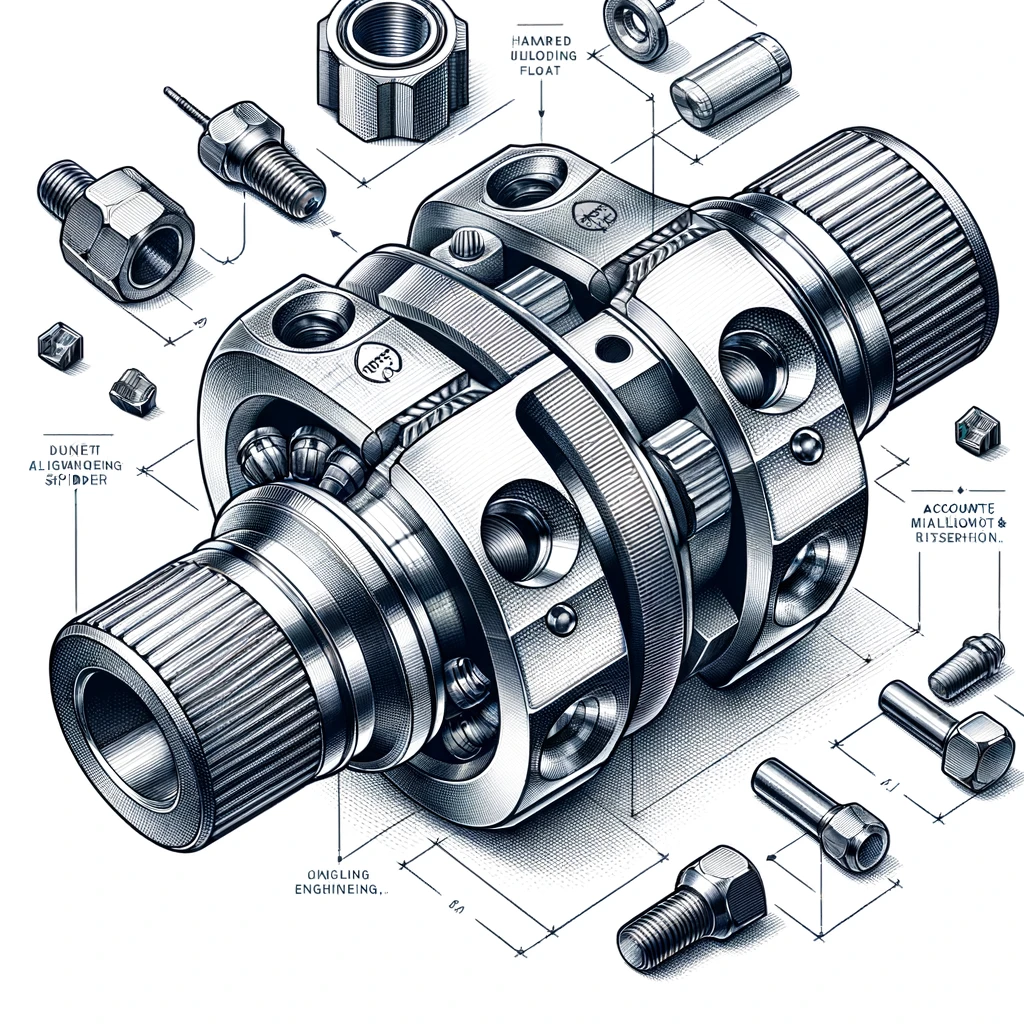

The key to the adaptability of our L-Jaw Couplings lies in their design. The L-Jaw coupling consists of two hubs and a spider, allowing for a variable amount of misalignment and end float. This design is inherently flexible, robust, and can handle minor misalignments typical in different setup orientations.

By using high-quality materials and precision engineering, we ensure that each component can withstand the varying stresses encountered in different operational planes. This robust construction leads to a longer lifespan and higher reliability, irrespective of the application’s orientation.

What applications benefit most from versatile coupling solutions?

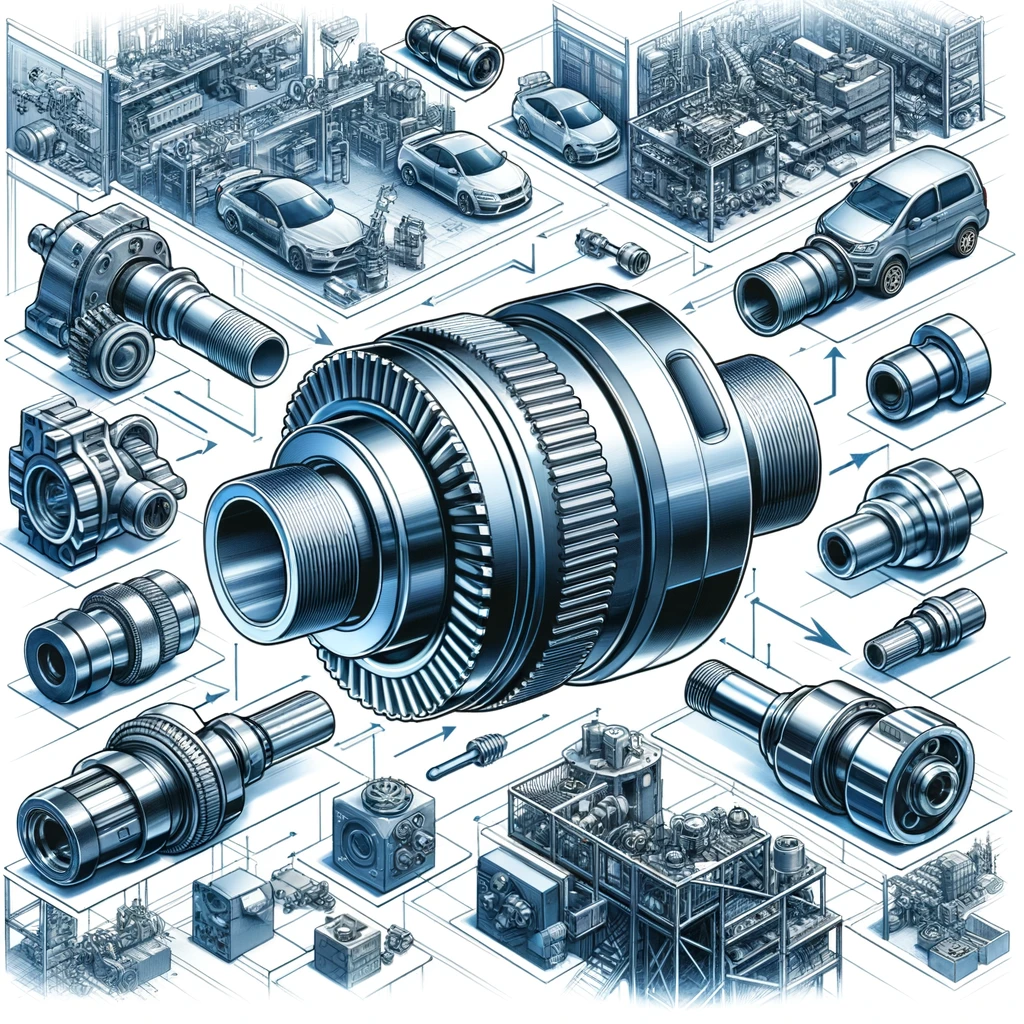

Versatile couplings like ours find their place in numerous applications—from large-scale industrial machinery to compact commercial equipment. Industries such as automotive, aerospace, and manufacturing frequently employ our couplings in their assemblies. The ability to use the same coupling in multiple configurations simplifies inventory management and reduces operational complexities for our clients.

In addition, our international presence in markets like the USA, Mexico and Canada underscores the global trust in our products’ adaptability and performance.

Are there any limitations to using couplings in different orientations?

While our couplings are designed to be as versatile as possible, certain technical specifications must be considered to optimize performance and ensure safety across different orientations. Below is a comparative table illustrating key parameters and their recommended values for horizontal and vertical applications:

| Parameter | Horizontal Applications | Vertical Applications | Notes |

|---|---|---|---|

| Alignment Accuracy | ±0.5 mm | ±0.7 mm | More critical in vertical due to gravity effects |

| Torque Capacity | Up to 3000 Nm | Up to 2500 Nm | Reduced in vertical due to increased load impact |

| Rotational Speed | Up to 4000 rpm | Up to 3500 rpm | Slightly lower in vertical to accommodate axial forces |

| End Float | Up to 0.2 mm | Up to 0.1 mm | Stricter in vertical to prevent misalignment |

Utilizing data-driven analysis and continuous testing, we strive to enhance the adaptability of our products to meet even the most demanding applications.

Conclusion

At Autojare, we pride ourselves on pushing the boundaries of what our mechanical components can achieve. The ability of our L-Jaw Coupling Sets to operate effectively in both horizontal and vertical applications is a testament to our commitment to innovation and quality. As we continue to serve a diverse array of industries, we remain dedicated to providing solutions that not only meet but exceed the expectations of our valued customers worldwide.

| Product Model | Size (Outer Diameter mm) | Bore Diameter (mm) | NBR Model | Material | Weight (kg) | Torque Capacity (Nm) | Product Link |

|---|---|---|---|---|---|---|---|

| L075 | 45 | 12 | NBR-75 | HT250 Steel | 0.5 | 100 | Product Link |

| L090 | 58 | 15 | NBR-90 | HT250 Steel | 0.7 | 150 | Product Link |

| L095 | 65 | 18 | NBR-95 | HT250 Steel | 0.9 | 200 | Product Link |