In the realm of mechanical coupling, the question often arises: can L-Jaw Coupling Sets handle high torque applications? The short answer is, absolutely. L-Jaw couplings are designed to offer robust performance, enabling the transmission of significant torque while compensating for some axial, radial, and angular misalignment.

The need for reliable coupling in machinery cannot be overstated. They are the unsung heroes, silently ensuring that power is efficiently transmitted between two shafts, even in the harshest of conditions. But not all couplings are created equal. The L-Jaw Coupling, with its distinct design and composition, offers a unique blend of flexibility and strength that is crucial for high torque applications.

Why is Torque Handling Capacity Important?

In industrial applications, the torque handling capacity of a coupling signifies its ability to withstand the force transmitted between connected shafts. A higher capacity means more power can be transmitted without the risk of failure. The L-Jaw coupling achieves this through its high-quality materials and design, which distribute stress evenly and absorb shocks and vibrations, a vital feature for equipment like conveyors, pumps, and compressors.

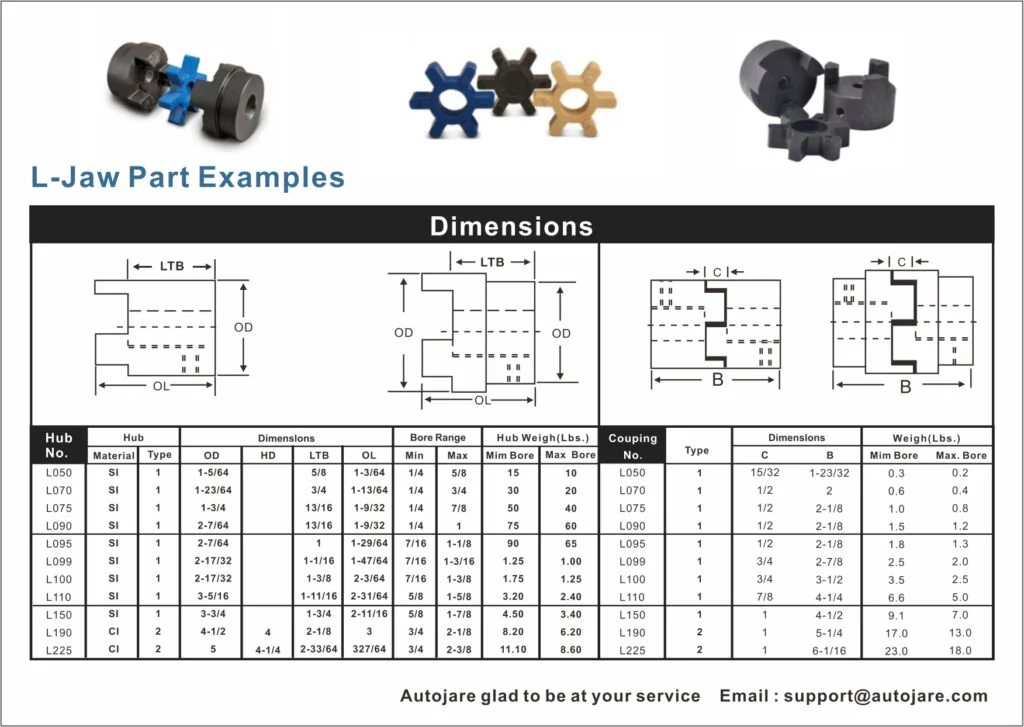

To illustrate the importance of torque handling capacity, consider the following table comparing the torque capacities of various coupling types:

| Coupling Type | Torque Capacity (Nm) | Ideal Application |

|---|---|---|

| L-Jaw Coupling | 190 – 24,000 | General industrial applications |

| Gear Coupling | 450 – 955,000 | Heavy industrial applications |

| Disc Coupling | 0.45 – 20,000 | Precision applications |

| Fluid Coupling | 10 – 2,300,000 | Variable speed and torque control |

Moreover, our commitment at Autojare is to not just produce an L-Jaw Coupling Set but to innovate in its design and material composition. This dedication has led us to develop couplings that are not only more efficient but also specifically tailored to handle higher torque applications without compromising on flexibility or alignment compensation.

What Makes Autojare’s L-Jaw Couplings Ideal for High Torque Applications?

Our L-Jaw Couplings are manufactured with precision engineering and the highest quality materials, ensuring they meet the rigorous demands of high torque applications. The key to our product’s effectiveness lies in its ability to maintain a balance between strength and flexibility, allowing it to absorb and distribute forces evenly, thereby reducing the risk of failure under high torque conditions.

Additionally, our close cooperation with factories allows us to maintain a high standard of quality control and adapt quickly to advancements in technology or material science. This, combined with our fast shipping times, ensures that our customers can rely on Autojare to support their needs promptly and efficiently.

The Importance of Choosing the Right Coupling

Choosing the right coupling is crucial for the smooth operation and longevity of machinery. The wrong choice can lead to frequent downtimes, increased maintenance costs, and, in the worst-case scenario, catastrophic failures. Our team at Autojare is dedicated to helping our customers select the best L-Jaw Coupling Set for their specific applications, taking into consideration factors such as torque requirements, shaft sizes, and alignment.

We also understand the importance of providing detailed specifications and data to support our claims. That’s why we have comprehensive technical sheets and data available on our website, offering insights into the torque capacities, dimensions, and material properties of our couplings.

Conclusion

L-Jaw Coupling Sets can handle high torque applications, and at Autojare, we are proud to be at the forefront of this technology. Our dedication to quality, innovation, and customer satisfaction sets us apart in the industry, and we continue to strive for excellence in every component we produce. Whether you’re dealing with brand chains, retailers, or online platforms, you can trust Autojare to provide coupling solutions that meet and exceed your high torque application needs.