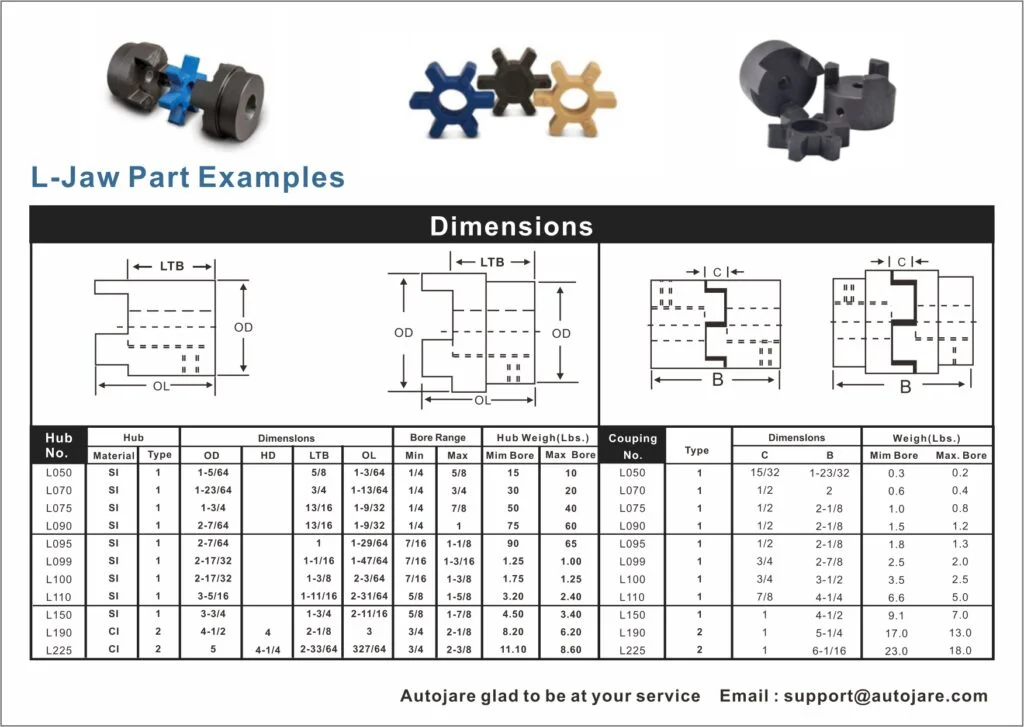

Identifying the ideal L-Jaw Coupling Set for your machinery involves understanding its operational environment and mechanical demands. It’s crucial to choose a coupling that aligns perfectly with your power transmission requirements to ensure efficient, reliable performance and extend the lifespan of both the coupling and your equipment.

As the CEO of Autojare, my team and I frequently encounter questions from customers regarding the selection of the right L-Jaw Coupling Set for various applications. Selecting the correct size and model isn’t merely about matching dimensions; it involves considering several technical parameters that influence the performance of your equipment.

What are the key factors to consider when selecting an L-Jaw Coupling Set?

When selecting an L-Jaw Coupling Set, it’s crucial to consider several key factors to ensure that the coupling meets the mechanical and operational requirements of your machinery. Below, I’ve provided a table that summarizes these key factors along with their typical data ranges and considerations:

| Factor | Description | Typical Data Range | Considerations |

|---|---|---|---|

| Torque Capacity | Ability of the coupling to transmit torque between connected shafts. | 10 Nm to 10,000 Nm | Should exceed motor’s peak torque by 25% for safety margin. |

| Shaft Size | Diameter of the shafts the coupling needs to connect. | 6 mm to 100 mm | Coupling must fit shafts snugly without any play. |

| RPM (Speed) | Maximum operational speed of the coupling. | 100 RPM to 10,000 RPM | Higher speeds may require couplings with better dynamic balance. |

| Material | The composition of the coupling. | Rubber, Polyurethane, Hytrel | Selected based on environmental resistance and torque transmission. |

| Misalignment | Tolerance for shaft misalignment. | Up to 1 degree angular misalignment | Choose couplings that can handle expected misalignment levels. |

| Temperature Range | The operational temperature range the coupling can withstand. | -40°C to +100°C | Ensure the material and design are suitable for operational climate. |

| Environmental Conditions | Conditions like moisture, chemicals, and dust exposure. | Corrosive, wet, abrasive | Material and design should resist environmental challenges. |

This table provides a comprehensive overview of what to consider when choosing an L-Jaw Coupling Set. It helps ensure that the selected coupling not only fits physically but also aligns with the operational dynamics and environmental conditions of your application.

In addition, the shaft size of both the driver and driven equipment must be considered. Our L-Jaw Couplings come in various sizes to fit different shaft diameters, and it’s crucial to ensure that the coupling fits snugly without any play, as this could lead to premature wear or failure.

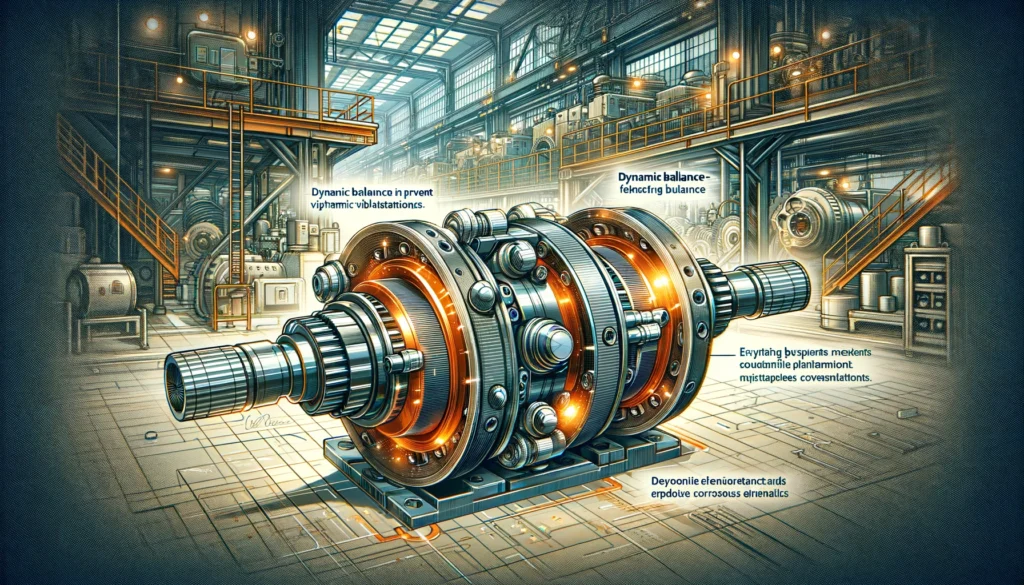

How do RPM and environmental factors influence coupling selection?

Another important factor is the operational speed (RPM) of your machinery. Higher speeds may require a coupling with better dynamic balance to avoid vibrations and potential damage. Environmental conditions such as temperature, humidity, and exposure to corrosive elements also play a critical role in selecting the right material and type of coupling to withstand these conditions.

By considering these aspects, you can avoid common pitfalls such as selecting a coupling that is ill-suited for high-temperature environments or one that cannot handle the RPM of your machinery.

Can alignment and misalignment tolerance impact my choice?

Yes, alignment is critical. L-Jaw Couplings are favored for their ability to tolerate some degree of misalignment between shafts. However, excessive misalignment can lead to rapid wear and tear, so it’s important to choose a coupling that offers the right balance between flexibility and rigidity. Our couplings are designed to handle angular, parallel, and axial misalignment within specific tolerances.

When evaluating potential misalignment, consider both the type and the amount of misalignment your application might encounter. This will help in selecting a coupling that can perform optimally under such conditions without compromising on longevity or efficiency.

What about the importance of material and quality in couplings?

Material choice is paramount. At Autojare, we manufacture our L-Jaw Couplings using high-grade materials that ensure durability and performance under varying operational conditions. The materials we use are capable of withstanding high torque and harsh environments, making them suitable for a wide range of industrial applications from brand chains to large supermarket setups.

Moreover, our commitment to quality is reflected in our fast shipping times and cooperation with top-tier factories, ensuring that our customers receive products that not only meet but exceed industry standards.

Conclusion

Choosing the right L-Jaw Coupling Set involves more than just matching specifications; it requires a thorough understanding of your machinery’s operational dynamics and environmental conditions. At Autojare, we’re committed to helping you select the perfect coupling that ensures optimal performance, efficiency, and reliability for your applications. Our expertise and dedication to quality make us a trusted partner in your industrial endeavors.

| Product Model | Size (Outer Diameter mm) | Bore Diameter (mm) | NBR Model | Material | Weight (kg) | Torque Capacity (Nm) | Product Link |

|---|---|---|---|---|---|---|---|

| L075 | 45 | 12 | NBR-75 | HT250 Steel | 0.5 | 100 | Product Link |

| L090 | 58 | 15 | NBR-90 | HT250 Steel | 0.7 | 150 | Product Link |

| L095 | 65 | 18 | NBR-95 | HT250 Steel | 0.9 | 200 | Product Link |