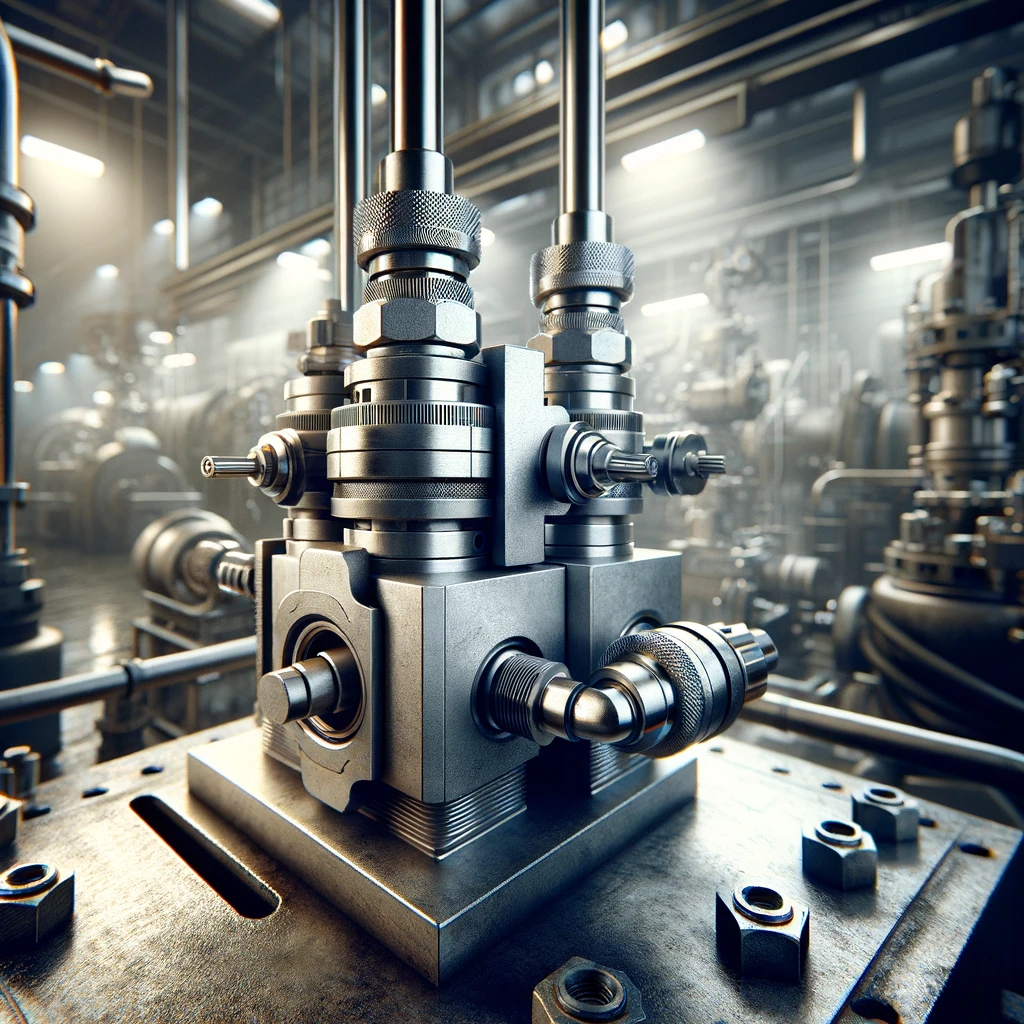

As the CEO of Autojare, operating from the heart of China and serving a vast B2C market across continents including the USA, Mexico, Canada, Europe, and Australia, I find myself frequently addressing inquiries about the resilience and performance of our signature product: the L-Jaw Coupling Set. Given our commitment to excellence and our strategic advantages over competitors—namely, our tight factory collaborations and swift delivery times—it’s imperative to shed light on a critical yet often underexplored aspect: the effect of temperature fluctuations on the operational integrity of L-Jaw Couplings.

Thermal variations can profoundly alter the material properties of the components constituting L-Jaw Coupling Sets, thereby influencing their performance, endurance, and reliability metrics. Engineered with precision to withstand diverse environmental conditions, our products guarantee optimal functionality across the varied climates of our global markets, ensuring uninterrupted operational excellence.

Delving into the thermomechanical behavior of L-Jaw Couplings unveils a complex interaction between material science and environmental conditions. This article aims to elucidate the significance of temperature as a determinant in the performance of L-Jaw Couplings, drawing upon our expertise and innovative approach to overcoming these challenges.

| Temperature Range (°C) | Material Behavior | Impact on Coupling Performance |

|---|---|---|

| -40 to -20 | Increased brittleness, higher risk of fracture | Potential for mechanical failure under load |

| -20 to 0 | Decreased elasticity, reduced shock absorption | Reduced damping capability, increased wear |

| 0 to 40 | Optimal material performance | Stable and reliable coupling performance |

| 40 to 60 | Slight expansion, manageable impact on performance | Minimal impact, maintain careful monitoring |

| 60 to 80 | Material expansion, increased wear and potential misalignment | Increased maintenance requirements, potential for performance degradation |

| 80 to 100 | Significant material softening, reduced vibration damping efficiency | Decreased operational lifespan, heightened maintenance |

| 100 to 120 | Risk of material degradation, severe impact on coupling integrity | Compromised structural integrity, risk of failure |

How do Elevated Temperatures Affect L-Jaw Couplings?

At elevated temperatures, the thermal expansion coefficient of materials becomes a pivotal factor. For instance, steel, a common material used in L-Jaw Couplings, has a thermal expansion coefficient of approximately 12×10^-6 /°C. This means that for every degree Celsius increase in temperature, a steel component would expand 12 millionths of its length. Considering a 100mm steel coupling hub, a temperature increase from 20°C to 80°C would result in a linear expansion of approximately 0.072mm. While this might seem negligible, in the realm of precision mechanical components, such expansion can lead to significant misalignment issues and increased wear over time.

Furthermore, the performance of elastomeric elements, vital for vibration damping and shock absorption within L-Jaw Couplings, degrades at high temperatures. An elastomer’s effective temperature range is typically between -40°C to +120°C. However, as temperatures approach the upper limit, the material’s modulus of elasticity decreases, leading to softer material properties. At 80°C, the damping material could experience a reduction in its stiffness by as much as 50%, significantly impairing its ability to absorb and dampen vibrational energy. This reduction in damping capacity can elevate the risk of resonance in the drivetrain, leading to premature wear or failure of the coupling and connected machinery.

It’s also critical to consider the cumulative impact of elevated temperatures over time. Continuous exposure to high temperatures can accelerate the aging process of the elastomeric spider, leading to hardening, cracking, and eventual failure. Studies have shown that for every 10°C increase in temperature above an elastomer’s recommended operating range, the aging rate of the material doubles, drastically reducing its service life.

In summary, elevated temperatures affect L-Jaw Couplings by inducing material expansion, altering the mechanical properties of elastomeric dampening elements, and accelerating the aging and degradation of these materials. These factors collectively compromise the coupling’s performance, necessitating careful material selection, design considerations, and temperature management strategies to ensure reliable operation under varying thermal conditions.

Precision Engineering: Mitigating Temperature Effects

Addressing temperature-induced challenges requires a multifaceted approach, integrating advanced material science, precision engineering, and empirical data analysis. Through the application of thermal analysis and finite element modeling, our engineering team assesses the thermal stress distribution and dimensional changes within the coupling assembly to ensure optimal performance under varying temperature conditions.

Our commitment to excellence is further underscored by our rigorous testing regimen, which includes thermal cycling tests to evaluate the coupling’s performance over a wide temperature range. These measures ensure that Autojare’s L-Jaw Couplings are not merely compliant with industry standards but are benchmarks of durability and reliability in extreme environments.

Empirical Evidence and the Path Forward

Guided by a philosophy of continuous improvement, we anchor our development process in empirical evidence and industry best practices. Our dedication to advancing the field of mechanical coupling technology is reflected in our ongoing research and development efforts, aimed at enhancing the thermal resilience of our L-Jaw Couplings.

Conclusion

The interplay between temperature and the operational integrity of L-Jaw Couplings encapsulates the challenges and innovations within the field of mechanical engineering. At Autojare, our relentless pursuit of engineering excellence, supported by empirical evidence and a deep understanding of material science, positions us as leaders in the production of L-Jaw Couplings. Our products are designed not just to meet but to exceed the expectations of a global clientele, ensuring seamless performance across the spectrum of environmental conditions.

Understanding how temperature affects the performance of L-type jaw couplings is crucial to ensuring long-term functionality and reliability. By selecting the right model and material, you can mitigate the risks associated with thermal expansion or contraction. To help you find the perfect fit for your specific needs, we’ve compiled a selection of our top L-type jaw couplings, available in various sizes and configurations. Explore the options below and click the links to learn more or make a purchase.

| Product Model | Size (Outer Diameter mm) | Bore Diameter (mm) | NBR Model | Material | Weight (kg) | Torque Capacity (Nm) | Product Link |

|---|---|---|---|---|---|---|---|

| L075 | 45 | 12 | NBR-75 | HT250 Steel | 0.5 | 100 | Product Link |

| L090 | 58 | 15 | NBR-90 | HT250 Steel | 0.7 | 150 | Product Link |

| L095 | 65 | 18 | NBR-95 | HT250 Steel | 0.9 | 200 | Product Link |