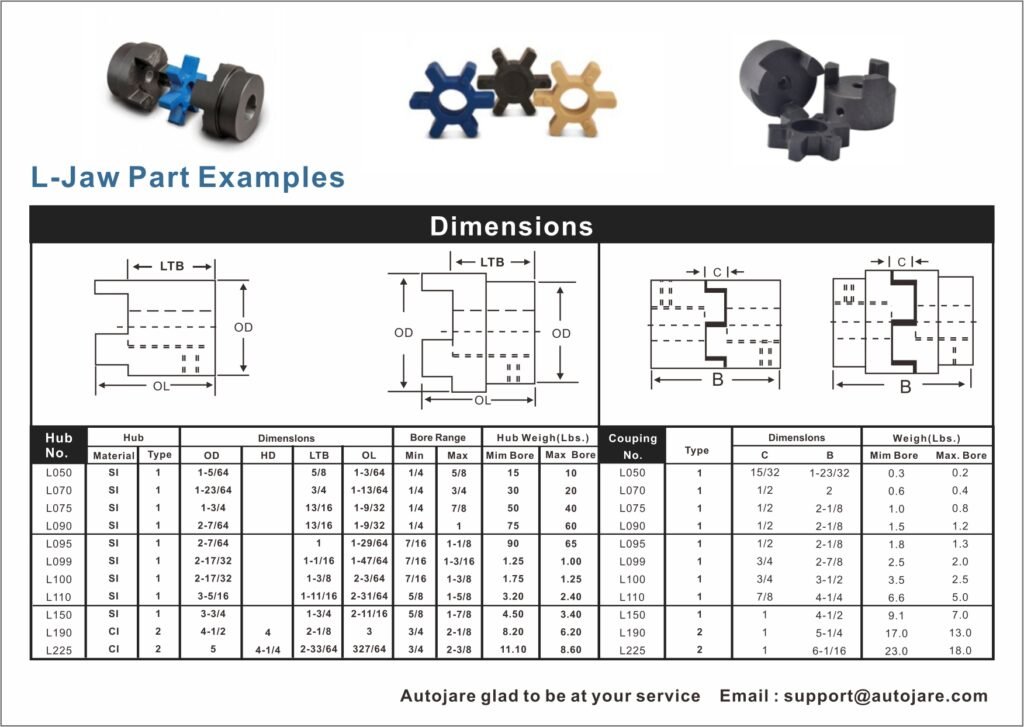

L-Jaw couplings are renowned for their versatility in accommodating misalignments, including angular, parallel, and axial, ensuring the longevity and efficiency of machinery. These couplings are ingeniously designed to mitigate the stresses and strains on shafts and bearings, promoting smoother operations and reducing downtime. By understanding the intricacies of how these couplings work, businesses can significantly enhance their machinery’s performance and durability.

Misalignment in machinery shafts can be detrimental, leading to increased wear, potential failures, and costly downtime. As the CEO of Autojare, I’ve seen firsthand the critical role that quality coupling systems play in addressing these issues. Our L-Jaw Coupling Sets are specifically engineered to provide a solution that is both efficient and reliable, ensuring that your machinery remains operational and productive.

What is Misalignment in Machinery?

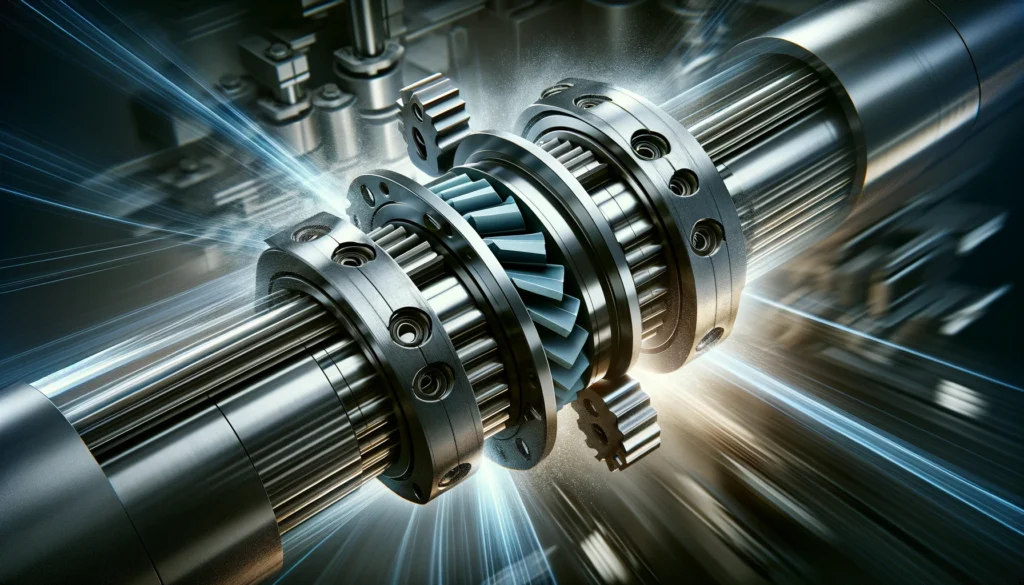

Misalignment in machinery refers to the condition where the central axes of two or more rotating components, such as shafts or gears, do not align perfectly when connected. This misalignment can be a result of several factors, including installation errors, wear and tear, thermal expansion, or the settling of foundations. Misalignment is a critical issue in rotating machinery because it can lead to excessive vibration, increased mechanical wear, premature failure of bearings and seals, and even catastrophic machinery breakdowns if not addressed properly.

There are three primary types of misalignment:

Angular Misalignment: This occurs when the shafts are tilted relative to each other, forming an angle at the point of connection. Angular misalignment can cause uneven rotational speeds and stresses along the connection, leading to potential damage over time.

Parallel Misalignment: Also known as offset misalignment, this happens when the shafts are parallel to each other but do not coincide along their rotational axis. This misalignment can result in uneven distribution of forces across the machinery components, potentially causing uneven wear and tear.

Axial Misalignment: This type involves the shafts being misaligned along their longitudinal axes, either too close or too far from each other. Axial misalignment can affect the operational efficiency of the machinery, causing issues with power transmission and increasing the likelihood of mechanical failures.

How Does L-Jaw Coupling Address Angular Misalignment?

Angular misalignment occurs when the shafts are inclined at an angle to each other. Our L-Jaw Coupling Sets are designed with a unique jaw and spider configuration that allows for flexibility in angular movement. This design accommodates angular misalignment up to 1 degree, effectively reducing stress on the shafts and bearings. The resilience of the elastomeric material used in the spider also absorbs shock and dampens vibrations, enhancing overall machinery performance.

And What About Parallel Misalignment?

Parallel misalignment, also known as offset misalignment, is a condition where the axes of connected shafts are parallel but displaced from each other. This displacement means that the shafts do not share a common centerline, leading to potential inefficiencies and increased wear on machinery components. Parallel misalignment can occur due to improper installation, component wear, or thermal expansion, and requires precise correction to avoid significant machinery damage.

To effectively illustrate the impact of parallel misalignment and the critical thresholds for various machinery types, the following table provides a simplified overview:

| Machinery Type | Tolerance for Parallel Misalignment (inches/mm) | Potential Effects of Exceeding Tolerance |

|---|---|---|

| High-Speed Turbines | 0.001 / 0.025 | Increased bearing wear, reduced efficiency |

| Pumps | 0.002 / 0.050 | Seal wear, vibration, and potential leaks |

| Electric Motors | 0.003 / 0.075 | Bearing stress, overheating, and energy loss |

| Conveyor Systems | 0.005 / 0.127 | Belt wear, uneven load distribution, breakdowns |

| General Industrial Machinery | 0.004 / 0.100 | Increased maintenance costs, reduced lifespan |

This table highlights the importance of maintaining precise alignment in machinery to ensure optimal performance and longevity. The tolerance levels for parallel misalignment vary depending on the type of machinery and its operational speed and load. Exceeding these tolerance levels can lead to a range of issues, from increased operational costs to the potential for machinery failure.

Correcting parallel misalignment involves realigning the machinery components to ensure their axes are both parallel and co-linear. This process typically requires specialized equipment, such as dial indicators or laser alignment tools, and skilled technicians to achieve the necessary precision. Regular maintenance checks are also crucial to identify and correct misalignment issues before they lead to significant damage or operational disruptions.

Addressing Axial Misalignment with L-Jaw Couplings

Axial misalignment refers to the condition where the shafts are positioned in a line but with a gap or overlap between them. The L-Jaw Coupling’s spider allows for axial movement, providing the necessary flexibility to accommodate end float up to ±0.2 inches. This capability is crucial for applications where thermal expansion or contraction of shafts occurs, ensuring the coupling maintains its performance without compromising the alignment.

By integrating Autojare’s L-Jaw Coupling Sets into your machinery, you leverage a solution that not only addresses misalignment issues but also contributes to the machine’s overall efficiency and longevity. Our focus on quality, coupled with our fast shipping times and high cooperation from factories, ensures that we remain competitive and reliable in the global market.

The Impact of Precise Coupling on Machinery Life

Utilizing couplings that accurately accommodate misalignments is paramount in prolonging machinery life. It minimizes wear on components, reduces vibration, and lowers the risk of unexpected failures. At Autojare, we understand the importance of precision in every product we develop. Our L-Jaw Coupling Sets are a testament to our commitment to excellence and our dedication to supporting the success of our customers’ businesses.

In conclusion, the L-Jaw Coupling Set from Autojare represents a superior solution for managing misalignments in machinery. Whether it’s angular, parallel, or axial misalignment, our products are designed to ensure maximum efficiency and durability. As we continue to innovate and improve, we remain dedicated to providing our customers with the best possible solutions for their mechanical connection needs.