As the CEO of Autojare, I constantly field questions regarding the compatibility of our L-Jaw Coupling Sets with various industrial standards. In this fast-evolving industrial landscape, understanding these compatibility issues is crucial for integrating new components into existing systems. Our commitment at Autojare is not just to meet but exceed industry standards, ensuring our products are a reliable choice for global industries.

Our L-Jaw Coupling Sets are engineered to comply with rigorous international and national standards, guaranteeing high performance and reliability across different industrial applications.

L-Jaw couplings play a vital role in a range of machinery by transmitting torque and accommodating shaft misalignment, which protects the equipment from stress and potential damage. This functionality is essential in industries from agriculture to aerospace, highlighting the importance of universal standard compliance in our manufacturing processes.

What Are the Key Standards for L-Jaw Couplings?

To ensure our products can be used worldwide, they are designed to meet specific standards set by prominent organizations. ISO (International Organization for Standardization) and ASTM (American Society for Testing and Materials) are two such bodies that define the performance and quality requirements for industrial components, including couplings.

How Do We Ensure Compliance at Autojare?

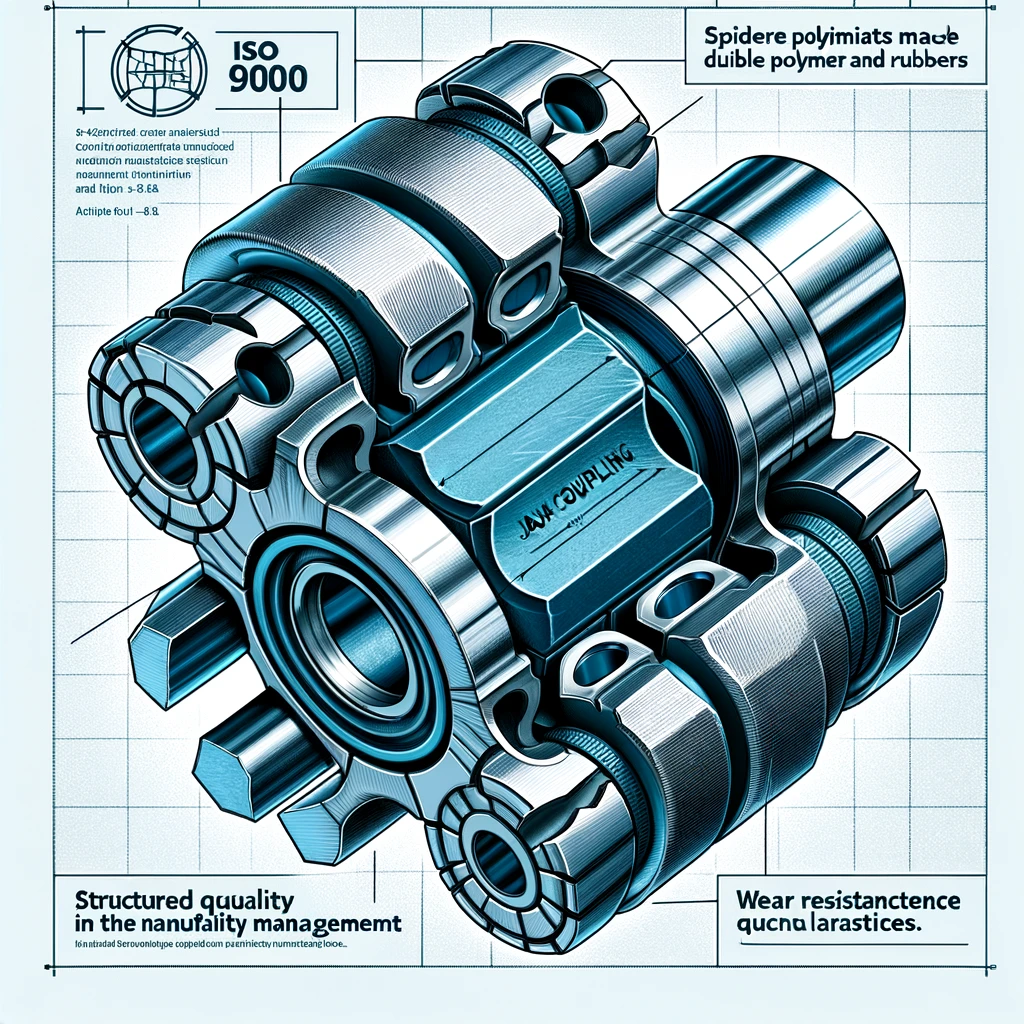

At Autojare, compliance starts in the design phase. Our L-Jaw Coupling Sets are manufactured in accordance with ISO 9001 quality management systems. This certification is more than a benchmark; it is part of our culture, ensuring that every product from our assembly line is robust and reliable.

| Step | Process | Standard |

|---|---|---|

| Design | Incorporate compliance requirements into product design. | ISO 9001 |

| Material Selection | Use high-quality materials that meet durability tests. | ISO 14001 |

| Manufacturing | Follow controlled processes to ensure product consistency. | ISO 9001 |

| Testing & Verification | Perform rigorous testing to confirm standard compliance. | ISO 17025 |

This structured approach not only ensures that every product from our assembly line is robust and reliable but also aligns with our ISO 9001 quality management system certification. This integration of high standards into every step of our operation guarantees the reliability and performance of our products across global markets.

We use premium materials for all our coupling components, especially the spider inserts, which are made from durable polymers and rubbers. These materials are chosen for their superior wear resistance and operational resilience, meeting stringent quality standards that safeguard the longevity and efficiency of the coupling in diverse operating conditions.

Are Regional Standards Also Considered?

Indeed, our global footprint requires adherence to regional as well as international standards. In Europe, our products carry the CE mark, signifying that they meet the EU’s safety, health, and environmental protection requirements. For North America, we comply with ANSI (American National Standards Institute) standards, which are critical for industries such as energy and manufacturing in those markets.

| Region | Standard | Description |

|---|---|---|

| Europe | CE Mark | Ensures products meet EU safety, health, and environmental protection requirements. |

| North America | ANSI Standards | Essential for industries such as energy and manufacturing, ensuring compliance with American national standards. |

| Australia | AS/NZS | Complies with Australian and New Zealand standards, crucial for products sold in these markets. |

What Does This Mean for Our Customers?

Choosing our L-Jaw Coupling Sets means opting for a product that not only meets but often exceeds the necessary industrial standards. Whether you are in the USA, Mexico, Canada, Europe, or Australia, using our couplings ensures that your equipment operates efficiently and complies with local regulations. This commitment to quality and compliance helps prevent downtime and simplifies maintenance processes.

Conclusion

Autojare’s dedication to producing L-Jaw Coupling Sets that are compatible with various industrial standards is unwavering. We believe in building products that not only meet but exceed the needs of our diverse clientele, ensuring reliability, efficiency, and compliance across all applications. Trust Autojare to keep your operations running smoothly, wherever you are in the world.