Need More Details?

Looking for a catalog or have questions about our jaw couplings? We’re here to assist with any inquiries you have.

Email us at Support@autojare.com or Sales@autojare.com

Our high-performance jaw couplings are designed to provide reliable and durable connections in various applications.

Looking for a catalog or have questions about our jaw couplings? We’re here to assist with any inquiries you have.

Email us at Support@autojare.com or Sales@autojare.com

A: At AUTOJARE, we specialize in producing high-quality L-type jaw couplings, designed to provide exceptional performance and durability.

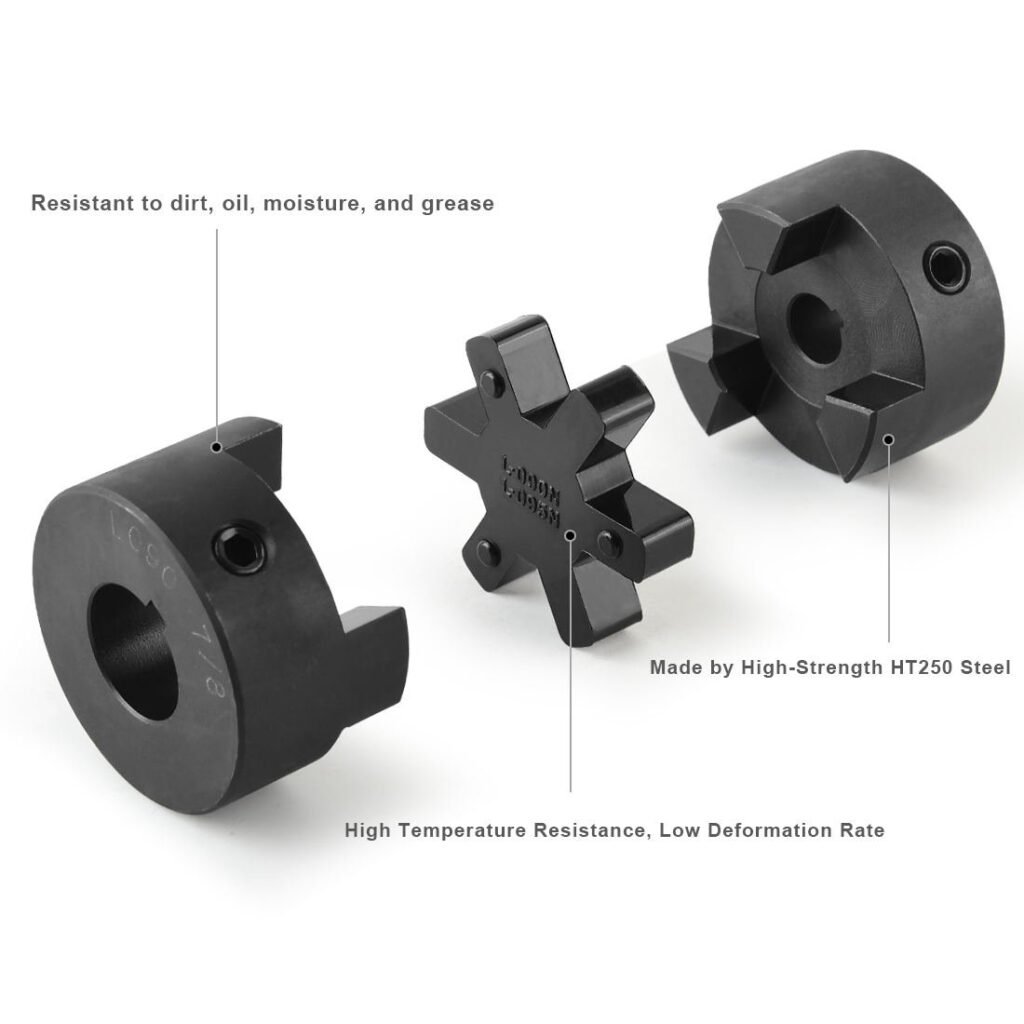

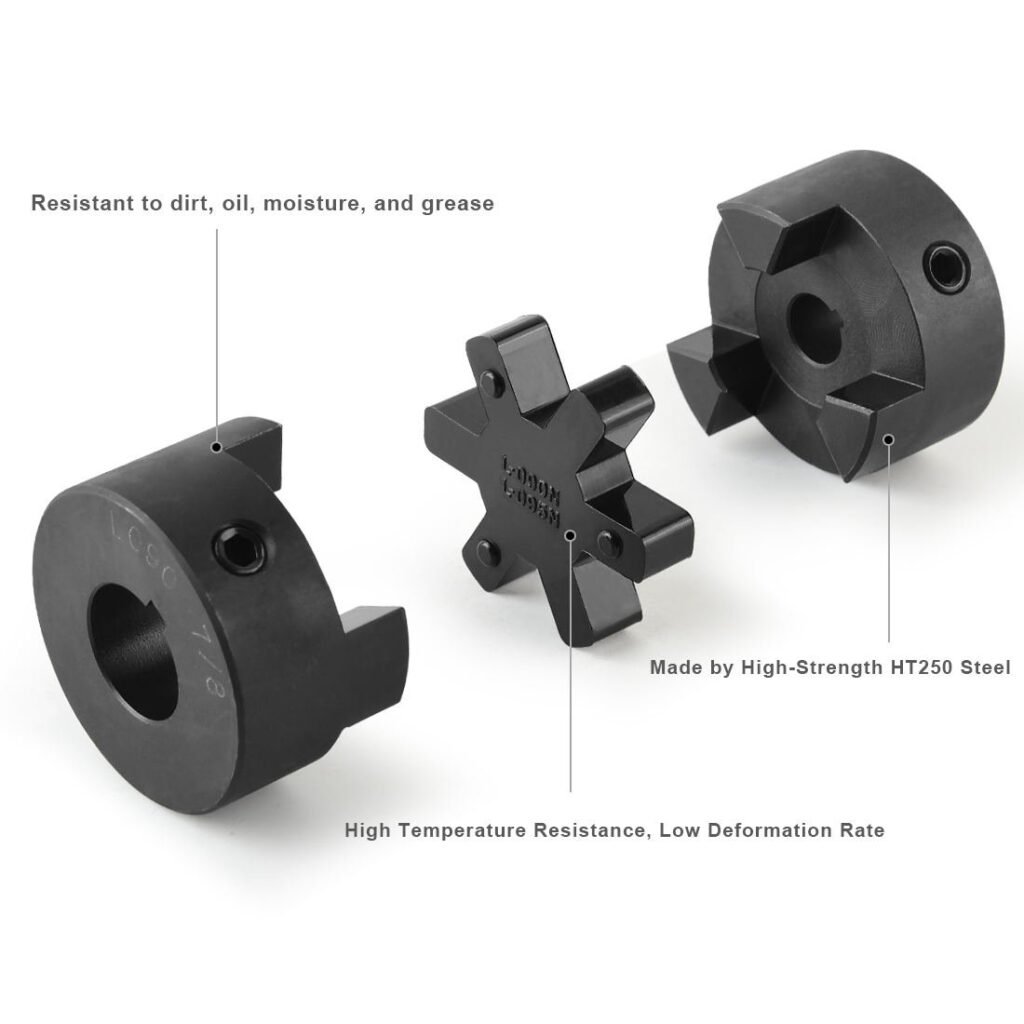

Material: Our couplings are crafted from high-strength HT250 steel, known for its superior durability and resistance to wear. This material choice ensures that AUTOJARE couplings stand up to even the most demanding industrial environments.

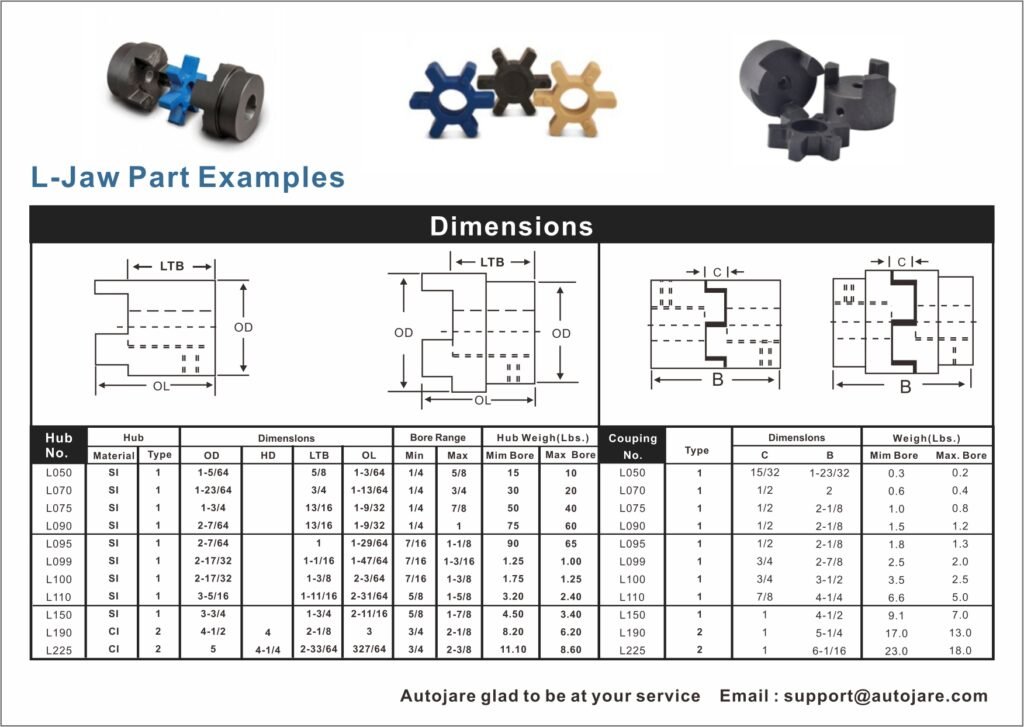

Dimensions: The dimensions are tailored to match the L075, L090, L095, L100, and L110 specifications, making them an ideal replacement for these sizes.

Torque Capacity: Engineered for robust performance, AUTOJARE couplings provide a reliable torque capacity that aligns with the needs of your specific application.

A: 1.Check Compatibility: Ensure the coupling matches your equipment’s shaft size and torque needs.

2.Align the Shafts: Position the shafts as closely aligned as possible using alignment tools if available.

3.Mount the Hubs: Slide the hubs onto the shafts, position them correctly, and insert the spider element between them for L-type jaw couplings.

4.Secure the Hubs: Tighten the set screws or bolts evenly, making sure the hubs are firmly in place.

5.Final Check: Recheck the alignment and run the equipment at low speed to ensure everything is functioning smoothly.

If you have any questions or run into issues, our AUTOJARE support team is here to assist!

A: Quality is a cornerstone of the AUTOJARE brand, and our L-type jaw couplings are no exception. Manufactured from high-strength HT250 steel, these couplings are built to last, offering superior resistance to wear and tear.

A: Our couplings are manufactured to meet high-quality standards and are designed for long-lasting durability. They are compliant with industry standards such as ISO, and undergo rigorous testing for performance and reliability. Additionally, the materials used are certified to meet RoHS environmental and safety standards. Our couplings are known for their resistance to wear and tear, making them ideal for both demanding industrial applications and regular use.

A: We offer a hassle-free return policy. If the coupling does not meet your expectations or is incompatible with your equipment, you can return it within 30 days for a full refund or exchange. The product must be in its original condition, and return shipping may apply. Additionally, our after-sales support team is available to assist with any installation, maintenance, or operational questions you may have. We are committed to ensuring your satisfaction with our products.

A: We provide various shipping options, including standard and expedited services. The cost depends on your location, and we ensure secure packaging with no special requirements.

A: Orders are typically processed and shipped within 1-2 business days. Delivery times vary depending on your location, but most orders arrive within 3-7 business days.

A: We offer several shipping options, including standard, expedited, and express delivery. Shipping costs depend on your location and the chosen delivery method. Our couplings are securely packaged to prevent damage during transit.

A: Yes, AUTOJARE offers customization options for large orders. We can tailor the couplings to specific requirements, including different bore sizes, finishes, or other modifications. Please contact our sales team to discuss your needs, and we’ll work with you to create the perfect solution.

A: The AUTOJARE L-Jaw Coupling Set is designed to accommodate various types of misalignment:

Angular Misalignment: The elastomeric spider element within the coupling allows for slight angular deviations between the two shafts, reducing stress and preventing damage to the coupling or connected equipment.

Parallel Misalignment: The flexible spider also absorbs minor parallel misalignments, ensuring smooth operation without excessive wear.

Axial Misalignment: The coupling can handle small amounts of axial movement, allowing the shafts to move slightly along their axis without compromising the coupling’s performance.

Overal, our L-Jaw Coupling Set designs helps protect your machinery by accommodating these common misalignments, extending the lifespan of both the coupling and the connected equipment.

In the realm of mechanical engineering and design, one might ponder the significance of what seems like a niche component: the L-Jaw Coupling Kit. This curiosity often arises from the critical role such components play in the seamless operation of machinery, yet their subtlety in the grander scale of manufacturing and mechanical systems can lead to them being overlooked.

L-Jaw Couplings are pivotal in connecting two shafts while also compensating for minor misalignments and absorbing moderate shock loads. This capability not only enhances the longevity of the machinery but also ensures its efficient operation. Designed with versatility in mind, these couplings can be utilized in various applications, ranging from power transmission to motion transfer systems.

At Autojare, our journey into specializing in the production of L-Jaw Coupling Sets has been driven by a commitment to excellence and a deep understanding of our customers' needs. Our products stand at the intersection of reliability and innovation, serving as a testament to our dedication to quality.

The choice of an L-Jaw Coupling comes down to its unparalleled flexibility and durability. These couplings are adept at handling a wide range of operational demands, making them a staple in various industrial settings. But what sets the L-Jaw Coupling apart from other types of couplings?

Bold keywords such as flexibility, durability, and operational demands are not just buzzwords; they encapsulate the essence of what L-Jaw Couplings offer. Their design allows for the accommodation of misalignment up to 1 degree and end float up to 0.8 mm, which, in turn, translates to a reduction in the wear and tear on connected equipment.

To further elucidate the advantages of L-Jaw Couplings over other coupling types, consider the following comparison chart:

| Feature | L-Jaw Coupling | Gear Coupling | Chain Coupling | Elastomeric Coupling |

|---|---|---|---|---|

| Misalignment Tolerance | High | Moderate | Low | High |

| Shock Absorption | Moderate | Low | Low | High |

| Maintenance | Low | High | Moderate | Low |

| Cost | Moderate | High | Moderate | Moderate |

| Installation Ease | High | Moderate | Moderate | High |

This table highlights the balance L-Jaw Couplings strike between misalignment tolerance, shock absorption, maintenance, cost, and ease of installation, making them an ideal choice for a wide array of applications.

L-Jaw Couplings operate on a simple yet effective principle of mechanical flexibility and alignment tolerance. These devices consist of three key components: two radially cut hub parts that attach directly to the shafts to be coupled and an elastomeric insert known as a "spider" that fits between them. The spider is made from a flexible material, typically polyurethane, which allows it to absorb shocks and accommodate misalignments between the shafts.

The unique feature of the L-Jaw Coupling is its L-shaped jaws, which engage with the spider. As the drive hub rotates, the spider transmits the torque to the driven hub, compensating for parallel, angular, and axial misalignments. This transmission of power occurs through the compression of the spider between the jaws of the hubs, which allows for the absorption of vibration and reduction of shock loads to the machinery.

The engineering behind L-Jaw Couplings enables them to provide a reliable and maintenance-free operation. Their ability to accommodate misalignment without generating excessive heat or wear on the component parts is a critical feature for applications requiring precision and durability. This makes L-Jaw Couplings an indispensable part of the mechanical assemblies in various industries, from heavy machinery to precision equipment.

The market for L-Jaw Couplings is competitive, but Autojare has carved out a niche for itself. Our advantage lies in our commitment to producing high-quality L-Jaw Coupling Sets with the support of our cooperative factories and our capability to ensure fast shipping times. We understand that in the world of B2C transactions, these factors are not just beneficial but essential.

Our dedication to quality and efficiency has not only earned us a loyal customer base but has also allowed us to stay ahead of our competitors. By focusing on these aspects, we ensure that our customers receive the best possible product in the shortest amount of time.

As the CEO of Autojare, I have overseen the development and distribution of our L-Jaw Coupling Sets, ensuring that each product meets our high standards. Our team is comprised of experts in the field of mechanical engineering, and we leverage this expertise to provide our customers with not just a product, but a solution.

Whether you're a brand chain, a large supermarket buyer, or an online retailer, partnering with us means gaining access to a product that is tailored to meet your needs. Our comprehensive understanding of the market, combined with our focus on customer satisfaction, makes us the ideal partner for your mechanical component needs.

The significance of L-Jaw Couplings in the broader context of mechanical systems cannot be overstated. At Autojare, our focus on producing top-quality L-Jaw Coupling Sets has positioned us as a leader in the field. By choosing us, you're not just acquiring a component; you're investing in reliability, efficiency, and innovation.

We will contact you within 1 working day, please pay attention to the email with the suffix “@Autojare.com”.

Copyright ©2024 Autojare. All Rights Reserved Copyright