When managing equipment or machinery, downtime and maintenance costs can take a big bite out of your productivity. Having a reliable and efficient power transmission solution becomes critical. One key component that helps ensure smooth and safe operation is the L-jaw coupling. But what exactly are the benefits, and why should you consider using it?

L-jaw couplings are mechanical devices used to transmit torque between two shafts. These couplings are ideal for use in machinery where the alignment between shafts can vary slightly. They are popular due to their flexibility, simplicity, and ability to absorb vibration. Let’s dive into the top benefits.

Maintaining your equipment can be a headache, but jaw couplings make it easier by reducing wear and tear. They’re designed to handle misalignment and shock loads efficiently, so you can extend the lifespan of your equipment. But what makes them stand out even more?

How Do Jaw Couplings Handle Misalignment?

One of the primary benefits of jaw couplings is their ability to manage angular misalignment, parallel misalignment, and even axial displacement between shafts. A slight misalignment is often unavoidable in real-world applications, but without a flexible coupling, it could result in damaged machinery. Jaw couplings prevent this by providing flexibility while still maintaining solid torque transmission.

Studies show that well-maintained jaw couplings can handle up to 1° of angular misalignment and 0.15 mm of parallel misalignment . This flexibility significantly reduces maintenance costs and prevents unexpected breakdowns.

Why Is Shock Absorption Important in Machinery?

When running machinery, shock loads—sudden increases in load—can be disastrous if your coupling can’t handle them. The elastomeric spiders within jaw couplings act as shock absorbers, dampening vibrations and protecting connected equipment. This not only prolongs the machinery’s operational life but also reduces noise levels, making the workplace more comfortable.

By reducing the impact of shock loads, you not only protect your machinery but also extend its operational life, ultimately improving your return on investment.

How Durable Are Jaw Couplings?

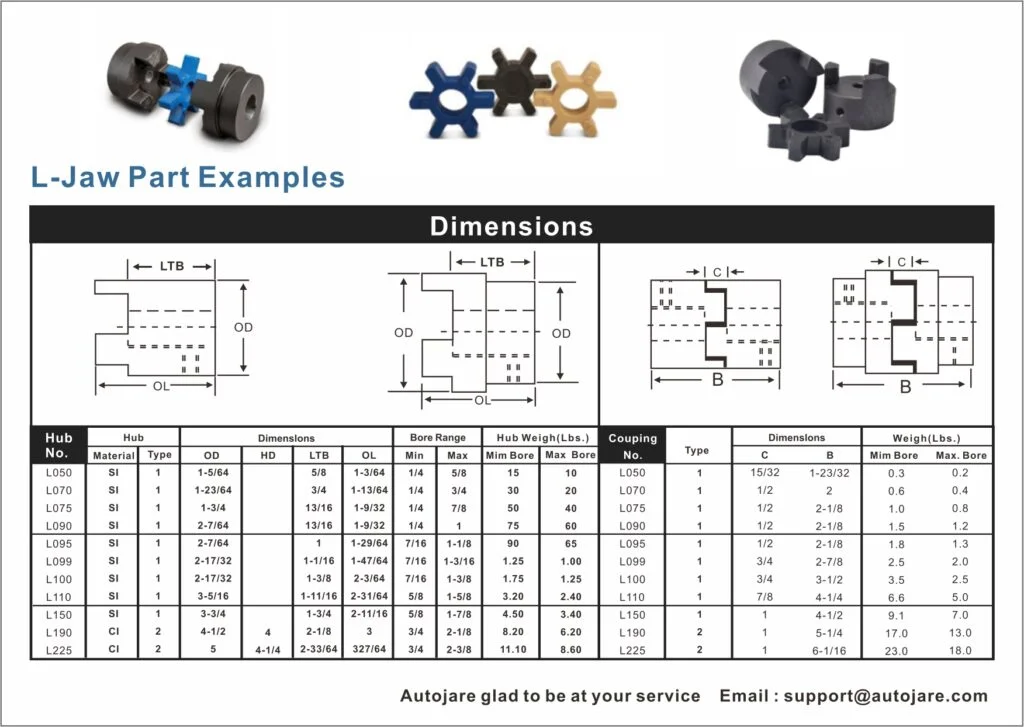

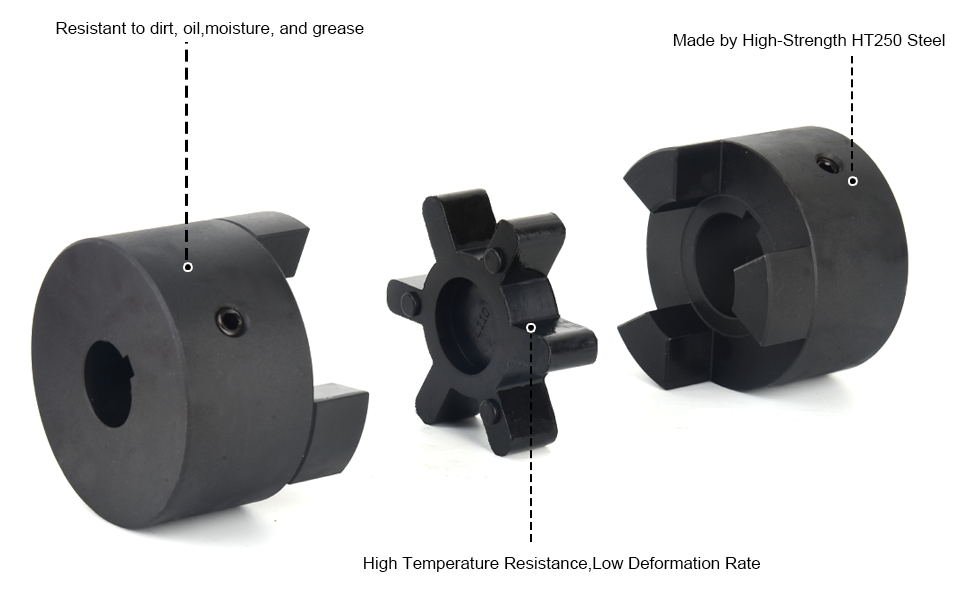

Durability is crucial in any power transmission system, and jaw couplings excel in this area. Their rugged design and materials, such as high-strength steel or cast iron, give them a long operational life, even in tough industrial environments. They are also resistant to corrosion, heat, and wear, making them ideal for outdoor or high-temperature applications.

According to industry standards, jaw couplings made from HT250 steel, like the ones we manufacture, can last for several years without needing replacement. This means fewer interruptions and more cost-effective operations.

What Types of Applications Can Benefit From Jaw Couplings?

Jaw couplings are versatile and can be found in a wide variety of applications. They are used in pumps, compressors, conveyors, and fans across many industries. Whether you are in manufacturing, agriculture, or the automotive industry, jaw couplings offer the reliability you need to keep things running smoothly.

How Does Vibration Dampening Benefit Your Equipment?

Another important feature of jaw couplings is vibration dampening. The elastomeric spiders within the couplings act as effective shock absorbers. They absorb vibrations from the power transmission, protecting delicate components and increasing their longevity. This results in quieter operation, which is a major plus in industrial environments where excessive noise is an issue.

The table below shows how vibration dampening through jaw couplings can improve the operational efficiency of your equipment:

| Benefit | Percentage/Impact | Description |

|---|---|---|

| Vibration Reduction | Up to 50% | Reduces vibrations from power transmission, preventing damage to sensitive equipment and extending operational life. |

| Noise Reduction | Significant reduction in noise | Quieter operation in industrial environments, creating a more comfortable workplace. |

| Downtime Minimization | Decreased by up to 30% | Prevents excessive wear on parts due to shock and vibration, resulting in fewer repairs and maintenance interruptions. |

| Cost Savings on Repairs | Up to 25% | Lower repair costs due to reduced wear and tear on components, thanks to effective vibration dampening. |

| Increased Equipment Longevity | Prolonged by up to 40% | Protects vital machinery components, increasing overall equipment life span and reducing the need for frequent part replacements. |

These data points illustrate how vibration dampening through jaw couplings not only extends equipment life but also minimizes downtime and repair costs. This makes them a highly efficient solution for industrial applications where reliability and durability are key.

How Easy Are Jaw Couplings to Install?

One of the standout benefits of L-jaw couplings is their ease of installation. These couplings consist of three simple parts: two hubs and an elastomeric spider. There’s no need for complex assembly, which reduces the time required to install them on machinery. This feature is particularly beneficial when you need to minimize downtime during maintenance or part replacement.

With only a few steps involved in the setup, even less experienced operators can manage the installation without extensive technical knowledge. This user-friendly design means reduced installation times, leading to increased efficiency across operations.

Are Jaw Couplings Easy to Maintain?

Yes! One of the significant advantages of jaw couplings is their low maintenance requirements. The elastomeric insert, which is responsible for absorbing shocks, can be easily replaced if it wears out. There’s no need to disassemble the entire coupling, which makes maintenance fast and cost-effective.

Regular inspection of the elastomer can ensure you replace it before it fails, preventing downtime. Statistics show that companies using jaw couplings can reduce maintenance costs by up to 25%.

Conclusion

Jaw couplings offer multiple benefits that make them an ideal choice for industries requiring efficient and reliable power transmission. Their ability to manage misalignment, absorb shock, reduce vibrations, and require low maintenance while offering long-lasting durability makes them a cost-effective solution for many applications. By incorporating jaw couplings into your machinery, you’ll enjoy reduced downtime, fewer maintenance needs, and a longer lifespan for your equipment.

At Autojare, we are committed to delivering high-quality L-jaw couplings with fast shipping and superior factory collaboration. Let us help you find the perfect coupling solution for your needs.

Here is the table with an additional column for product links in a format that you can copy:

| NBR | SKU | SIZE | Product Link |

|---|---|---|---|

| L075 | LZQ-001 | 1/2” to 3/4” L075 | [Insert Link] |

| L075 | LZQ-002 | 1/2” to 7/8” L075 | [Insert Link] |

| L075 | LZQ-004 | 1/2” to 5/8” L075 | [Insert Link] |

| L075 | LZQ-011 | 3/4” to 3/4” L075 | [Insert Link] |

| L075 | LZQ-012 | 1/2” to 1” L075 | [Insert Link] |

| L075 | LZQ-013 | 5/8” to 5/8” L075 | [Insert Link] |

| L075 | LZQ-014 | 5/8” to 3/4” L075 | [Insert Link] |

| L090 | LZQ-003 | 1/2” to 3/4” L090 | [Insert Link] |

| L090 | LZQ-018 | 1/2” to 1” L090 | [Insert Link] |

| L090 | LZQ-019 | 3/4” to 1” L090 | [Insert Link] |

| L090 | LZQ-020 | 1/2” to 7/8” L090 | [Insert Link] |

| L095 | LZQ-006 | 1/2” to 1” L095 | [Insert Link] |

| L095 | LZQ-007 | 1/2” to 3/4” L095 | [Insert Link] |

| L095 | LZQ-015 | 5/8” to 1” L095 | [Insert Link] |

| L095 | LZQ-016 | 1/2” to 7/8” L095 | [Insert Link] |

| L095 | LZQ-017 | 3/4” to 3/4” L095 | [Insert Link] |

| L100 | LZQ-021 | 3/4” to 1” L100 | [Insert Link] |

| L100 | LZQ-022 | 3/4” to 1-1/4” L100 | [Insert Link] |

| L100 | LZQ-023 | 3/4” to 1-1/8” L100 | [Insert Link] |

| L110 | LZQ-024 | 1” to 1-1/2” L110 | [Insert Link] |

| L110 | LZQ-025 | 1” to 1-3/8” L110 | [Insert Link] |