In the realm of mechanical engineering and design, one might ponder the significance of what seems like a niche component: the L-Jaw Coupling Kit. This curiosity often arises from the critical role such components play in the seamless operation of machinery, yet their subtlety in the grander scale of manufacturing and mechanical systems can lead to them being overlooked.

L-Jaw Couplings are pivotal in connecting two shafts while also compensating for minor misalignments and absorbing moderate shock loads. This capability not only enhances the longevity of the machinery but also ensures its efficient operation. Designed with versatility in mind, these couplings can be utilized in various applications, ranging from power transmission to motion transfer systems.

At Autojare, our journey into specializing in the production of L-Jaw Coupling Sets has been driven by a commitment to excellence and a deep understanding of our customers’ needs. Our products stand at the intersection of reliability and innovation, serving as a testament to our dedication to quality.

Why Choose an L-Jaw Coupling?

The choice of an L-Jaw Coupling comes down to its unparalleled flexibility and durability. These couplings are adept at handling a wide range of operational demands, making them a staple in various industrial settings. But what sets the L-Jaw Coupling apart from other types of couplings?

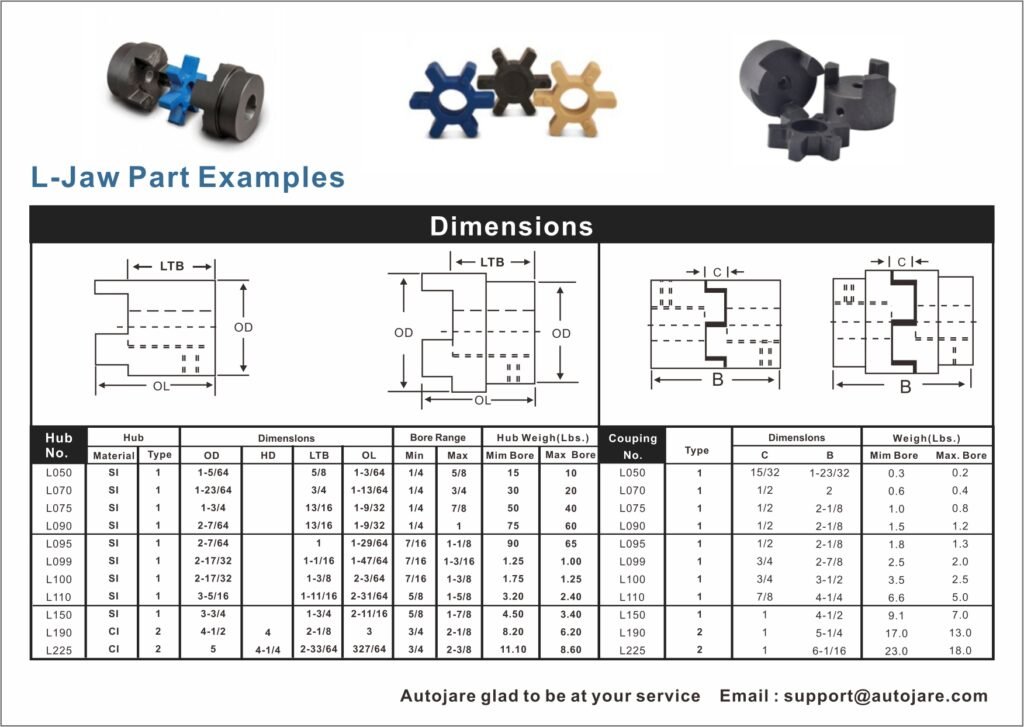

Bold keywords such as flexibility, durability, and operational demands are not just buzzwords; they encapsulate the essence of what L-Jaw Couplings offer. Their design allows for the accommodation of misalignment up to 1 degree and end float up to 0.8 mm, which, in turn, translates to a reduction in the wear and tear on connected equipment.

To further elucidate the advantages of L-Jaw Couplings over other coupling types, consider the following comparison chart:

| Feature | L-Jaw Coupling | Gear Coupling | Chain Coupling | Elastomeric Coupling |

|---|---|---|---|---|

| Misalignment Tolerance | High | Moderate | Low | High |

| Shock Absorption | Moderate | Low | Low | High |

| Maintenance | Low | High | Moderate | Low |

| Cost | Moderate | High | Moderate | Moderate |

| Installation Ease | High | Moderate | Moderate | High |

This table highlights the balance L-Jaw Couplings strike between misalignment tolerance, shock absorption, maintenance, cost, and ease of installation, making them an ideal choice for a wide array of applications.

How Do L-Jaw Couplings Work?

L-Jaw Couplings operate on a simple yet effective principle of mechanical flexibility and alignment tolerance. These devices consist of three key components: two radially cut hub parts that attach directly to the shafts to be coupled and an elastomeric insert known as a “spider” that fits between them. The spider is made from a flexible material, typically polyurethane, which allows it to absorb shocks and accommodate misalignments between the shafts.

The unique feature of the L-Jaw Coupling is its L-shaped jaws, which engage with the spider. As the drive hub rotates, the spider transmits the torque to the driven hub, compensating for parallel, angular, and axial misalignments. This transmission of power occurs through the compression of the spider between the jaws of the hubs, which allows for the absorption of vibration and reduction of shock loads to the machinery.

The engineering behind L-Jaw Couplings enables them to provide a reliable and maintenance-free operation. Their ability to accommodate misalignment without generating excessive heat or wear on the component parts is a critical feature for applications requiring precision and durability. This makes L-Jaw Couplings an indispensable part of the mechanical assemblies in various industries, from heavy machinery to precision equipment.

What Sets Autojare’s L-Jaw Couplings Apart?

The market for L-Jaw Couplings is competitive, but Autojare has carved out a niche for itself. Our advantage lies in our commitment to producing high-quality L-Jaw Coupling Sets with the support of our cooperative factories and our capability to ensure fast shipping times. We understand that in the world of B2C transactions, these factors are not just beneficial but essential.

Our dedication to quality and efficiency has not only earned us a loyal customer base but has also allowed us to stay ahead of our competitors. By focusing on these aspects, we ensure that our customers receive the best possible product in the shortest amount of time.

How Can You Benefit from Autojare’s Expertise?

As the CEO of Autojare, I have overseen the development and distribution of our L-Jaw Coupling Sets, ensuring that each product meets our high standards. Our team is comprised of experts in the field of mechanical engineering, and we leverage this expertise to provide our customers with not just a product, but a solution.

Whether you’re a brand chain, a large supermarket buyer, or an online retailer, partnering with us means gaining access to a product that is tailored to meet your needs. Our comprehensive understanding of the market, combined with our focus on customer satisfaction, makes us the ideal partner for your mechanical component needs.

Conclusion

The significance of L-Jaw Couplings in the broader context of mechanical systems cannot be overstated. At Autojare, our focus on producing top-quality L-Jaw Coupling Sets has positioned us as a leader in the field. By choosing us, you’re not just acquiring a component; you’re investing in reliability, efficiency, and innovation.