Are you looking for a reliable solution to connect different shafts without compromising machine efficiency? In industries ranging from automotive to heavy machinery, shaft couplings play a crucial role in maintaining functionality. If you’ve been wondering about the advantages and specific role of L-jaw couplings in machinery, this post will provide insights and solutions backed by years of expertise from Autojare.

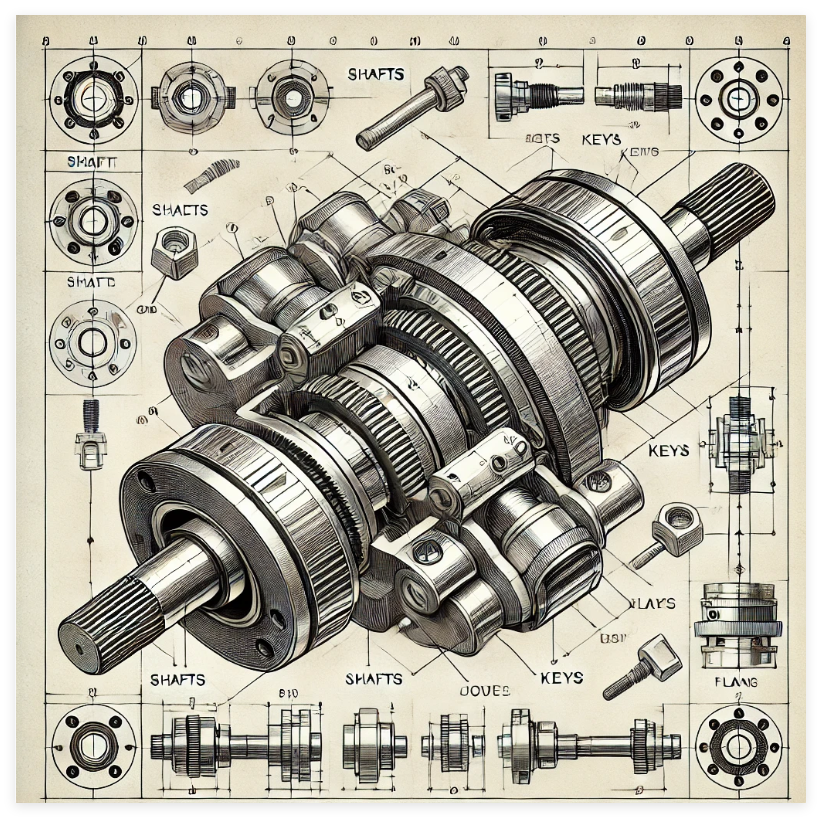

An L-jaw coupling functions as a reliable mechanical component, specifically designed to connect two shafts and transfer torque while accommodating some misalignment and vibrations. L-jaw couplings are known for their flexibility, ease of installation, and cost-effectiveness, making them widely popular in various applications. Let’s dive into the specifics of how an L-jaw coupling works and why it’s an ideal choice for many industries.

What Makes L-Jaw Couplings Effective for Industrial Use?

L-jaw couplings are commonly chosen because of their high torque capacity and ability to absorb shocks and vibrations effectively. These properties ensure that machinery operates smoothly even in challenging conditions, which is critical for maintaining productivity and reducing downtime. For example, studies show that using L-jaw couplings can increase the lifespan of machinery by up to 20%. Their versatility allows them to perform well in settings where precision and durability are paramount.

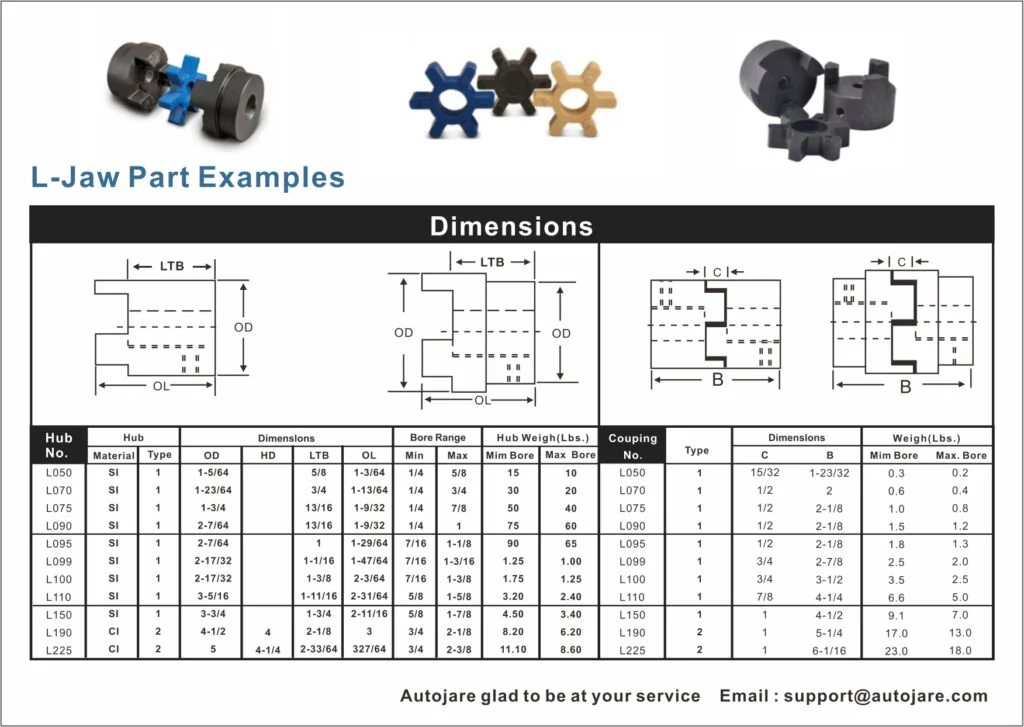

Additionally, these couplings are compatible with various shaft sizes and setups. The design flexibility allows manufacturers and operators to optimize performance according to specific requirements, enhancing overall efficiency.

How Does an L-Jaw Coupling Work?

At its core, an L-jaw coupling consists of three main components: two hubs and an elastomeric spider. The hubs connect to the shafts, and the spider sits between them, acting as a buffer to absorb shocks and reduce wear on the connected components. This design ensures smooth operation by managing angular, radial, and axial misalignment effectively.

Why Is Misalignment Compensation Important?

Misalignment in rotating machinery can cause significant issues, including vibrations, excessive wear, and even failure. The ability of an L-jaw coupling to handle minor misalignments (up to 1° angular misalignment) is a major reason it’s preferred in many applications, especially where precision is key.

Here’s a table to illustrate the importance of Misalignment Compensation in L-jaw couplings, showing the types of misalignments and their potential impacts on machinery:

| Type of Misalignment | Description | Impact on Machinery | L-Jaw Coupling Compensation |

|---|---|---|---|

| Angular Misalignment | Shafts are misaligned at an angle | Causes vibration and wear on bearings | Compensates up to 1° angle |

| Parallel (Radial) Misalignment | Shafts are not aligned along their length axis | Increases load on motor and coupling parts | Absorbs minor radial misalignments |

| Axial (End Float) Misalignment | Shafts move along their length due to thermal expansion or other forces | Can lead to shaft and bearing damage | Absorbs small axial movements to prevent damage |

What Are the Main Types of L-Jaw Couplings?

There are several types of L-jaw couplings, each tailored to specific uses and levels of performance. Key variants include standard, curved jaw, and spider-inserted couplings. The difference lies in the elastomeric material and its properties, which directly impact torque capacity, flexibility, and shock absorption.

For instance, a high-torque L-jaw coupling can handle loads up to 50 Nm while offering vibration damping properties. Such specifications make it suitable for heavy machinery, where maintaining a stable operation is essential.

How Durable Are L-Jaw Couplings?

Autojare’s L-jaw couplings are crafted with high-quality materials like steel and high-strength elastomers, ensuring long-lasting durability even under high loads and frequent use. Data shows that premium L-jaw couplings have a lifespan of 5-7 years under continuous operation. This extended life not only lowers maintenance costs but also contributes to higher operational efficiency.

Regular maintenance, such as checking for wear and ensuring proper alignment, can further prolong the life of the coupling. Properly maintained couplings reduce operational costs, saving companies up to 15% in yearly maintenance expenses.

Key Benefits of Using L-Jaw Couplings

- Shock Absorption: Reduces the impact of sudden torque changes, protecting both the motor and the connected equipment.

- High Flexibility: Easily accommodates minor misalignments, saving costs on precise alignment.

- Ease of Installation: Simple design allows for quick setup and replacement without specialized tools.

- Cost-Effectiveness: L-jaw couplings offer excellent value by balancing performance with affordability, especially in high-demand environments.

Are L-Jaw Couplings Suitable for Your Machinery?

If you work in industries like manufacturing, agriculture, or automotive, the answer is likely yes. L-jaw couplings provide the flexibility and durability necessary for heavy-duty applications, particularly where reliability is a top priority. Autojare’s line of couplings is designed with these industries in mind, ensuring they meet the demanding requirements of today’s industrial equipment.

How to Choose the Right L-Jaw Coupling for Your Needs?

Selecting the correct L-jaw coupling depends on factors like torque requirements, shaft sizes, and operational conditions. At Autojare, we help our customers find the ideal solution based on precise needs. For example, if you need a coupling that can withstand high torque in harsh environments, we recommend a steel-made L-jaw coupling with a reinforced elastomeric spider.

Do L-Jaw Couplings Require Maintenance?

While L-jaw couplings are low-maintenance, periodic checks are essential for optimal performance. Basic maintenance includes:

- Visual inspections to detect wear on the elastomeric spider.

- Torque checks to ensure the coupling remains secure.

- Alignment checks to minimize misalignment-related wear.

In an industrial setting, regular maintenance can reduce downtime by up to 30% and significantly extend the lifespan of your equipment.

What Makes Autojare L-Jaw Couplings Stand Out?

Our commitment at Autojare is to provide high-quality L-jaw couplings tailored to the needs of modern industries. We emphasize fast shipping, factory support, and compatibility across various industrial setups. This focus has earned us a reputation for reliability and high performance. Customers can rely on our L-jaw couplings to enhance their operational efficiency and reduce long-term costs.

Conclusion

In summary, L-jaw couplings offer a practical, effective solution for connecting shafts in industrial applications. Their unique design accommodates misalignment, absorbs shocks, and ensures smooth operation. At Autojare, we prioritize quality and durability, helping our clients across the USA, Canada, Europe, and beyond enhance their machinery’s performance. Reach out to us today to discuss your coupling needs and learn how we can support your business.

| NBR | SKU | SIZE | Product Link |

|---|---|---|---|

| L075 | LZQ-001 | 1/2” to 3/4” L075 | [Insert Link] |

| L075 | LZQ-002 | 1/2” to 7/8” L075 | [Insert Link] |

| L075 | LZQ-004 | 1/2” to 5/8” L075 | [Insert Link] |

| L075 | LZQ-011 | 3/4” to 3/4” L075 | [Insert Link] |

| L075 | LZQ-012 | 1/2” to 1” L075 | [Insert Link] |

| L075 | LZQ-013 | 5/8” to 5/8” L075 | [Insert Link] |

| L075 | LZQ-014 | 5/8” to 3/4” L075 | [Insert Link] |

| L090 | LZQ-003 | 1/2” to 3/4” L090 | [Insert Link] |

| L090 | LZQ-018 | 1/2” to 1” L090 | [Insert Link] |

| L090 | LZQ-019 | 3/4” to 1” L090 | [Insert Link] |

| L090 | LZQ-020 | 1/2” to 7/8” L090 | [Insert Link] |

| L095 | LZQ-006 | 1/2” to 1” L095 | [Insert Link] |

| L095 | LZQ-007 | 1/2” to 3/4” L095 | [Insert Link] |

| L095 | LZQ-015 | 5/8” to 1” L095 | [Insert Link] |

| L095 | LZQ-016 | 1/2” to 7/8” L095 | [Insert Link] |

| L095 | LZQ-017 | 3/4” to 3/4” L095 | [Insert Link] |

| L100 | LZQ-021 | 3/4” to 1” L100 | [Insert Link] |

| L100 | LZQ-022 | 3/4” to 1-1/4” L100 | [Insert Link] |

| L100 | LZQ-023 | 3/4” to 1-1/8” L100 | [Insert Link] |

| L110 | LZQ-024 | 1” to 1-1/2” L110 | [Insert Link] |

| L110 | LZQ-025 | 1” to 1-3/8” L110 | [Insert Link] |