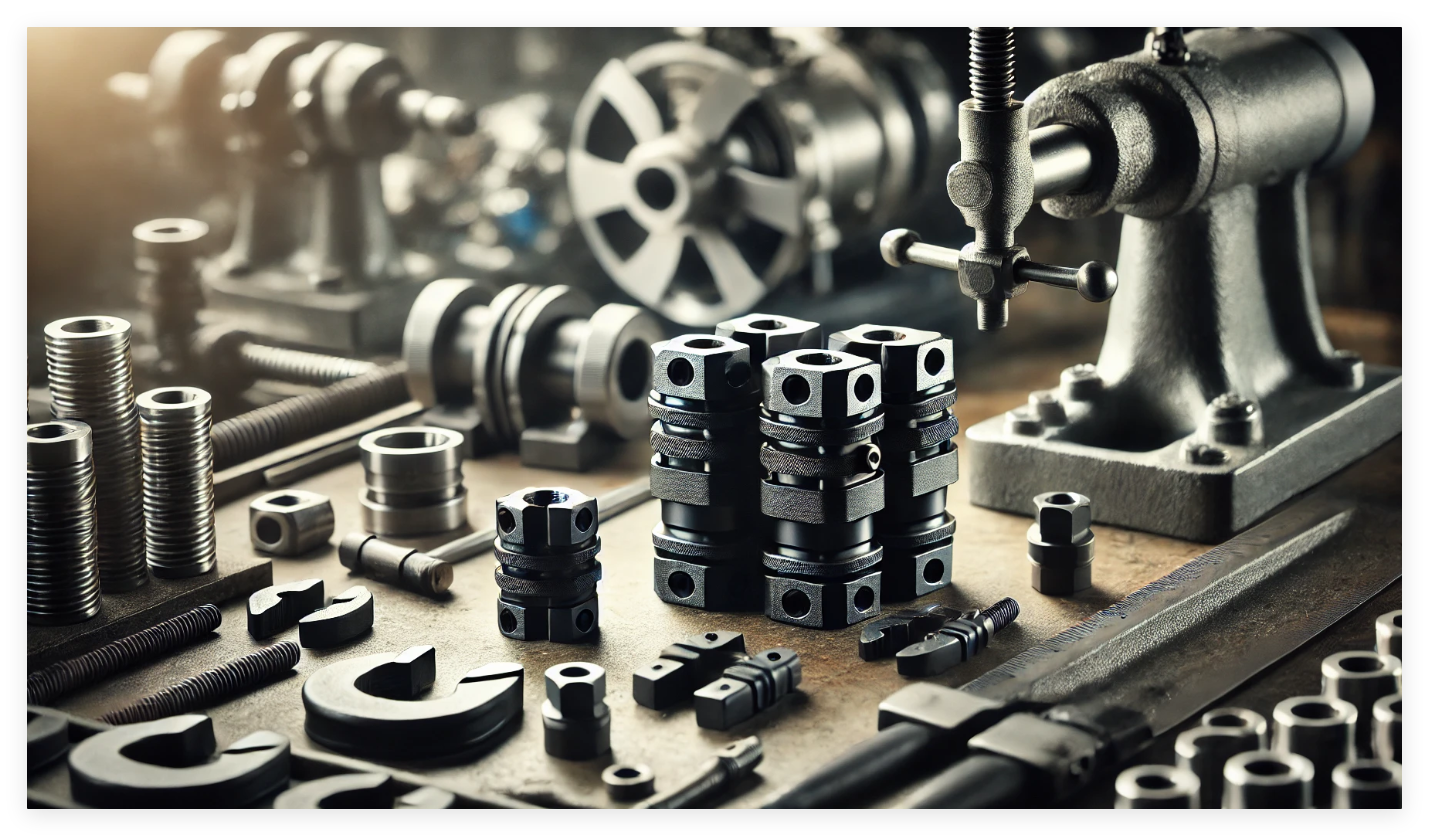

As the CEO of Autojare, I have always been fascinated by the intricacies of mechanical components, especially when it comes to the manufacturing of L-Jaw Couplings. These components are crucial in various machinery and vehicles, facilitating torque transmission between two shafts while accommodating misalignment.

In this blog post, I’ll delve into the specific materials used in the construction of L-Jaw Couplings, their properties, and why these materials are chosen for their roles in these essential components.

Understanding the choice of materials is crucial because it directly influences the durability, performance, and suitability of the couplings for different applications. Let’s take a closer look at what goes into making these pivotal parts.

Why Is Material Selection Important for L-Jaw Couplings?

Material selection in mechanical parts like L-Jaw Couplings is not merely about finding the toughest stuff out there. It’s about matching material properties to the demands of the application. This includes considering factors such as torque capacity, environmental resistance, price, and availability.

For instance, cast iron is a common choice for L-Jaw Couplings. It’s favored for its excellent vibration damping properties and good wear resistance, which are essential in applications involving heavy machinery.

What Are the Common Materials Used?

Here is a table summarizing the materials commonly used in the production of L-Jaw Couplings, along with their advantages and disadvantages:

| Material | Advantages | Disadvantages |

|---|---|---|

| Cast Iron | Excellent vibration damping, good wear resistance | Heavy, prone to corrosion |

| Aluminum | Lightweight, corrosion-resistant | Less wear-resistant, softer |

| Stainless Steel | Very strong, excellent corrosion resistance | Heavier, more expensive |

Each material brings specific benefits and potential drawbacks. For example, while aluminum is lighter, making it suitable for applications where weight is a concern, it doesn’t offer the same wear resistance as stainless steel or cast iron. These trade-offs are vital to consider during the design phase.

How Do Material Properties Affect Performance?

The performance of an L-Jaw Coupling hinges on the properties of the materials used. For instance, the hardness and toughness of cast iron allow it to withstand high torque loads and shock loads without failing. The flexibility of the material is also crucial as it needs to absorb and compensate for misalignment between connected shafts.

Additionally, the thermal stability of a material affects the coupling’s performance under varying operational temperatures. Materials like stainless steel maintain their strength and dimensional stability even at high temperatures, ensuring reliable performance across a range of conditions.

What About Advanced Materials?

In recent years, there has been a shift towards the use of composite materials and polymers in L-Jaw Couplings, especially in highly specialized applications. These materials can be engineered to provide specific properties such as reduced weight, increased corrosion resistance, or greater flexibility.

For example, polyurethane is used in the elastomeric spiders of L-Jaw Couplings, which are the flexible elements that actually absorb the misalignments and shocks. Polyurethane provides excellent wear resistance and flexibility, making it an ideal choice for this part of the coupling.

Are There Environmental Considerations?

Yes, the environmental impact of materials is also a key consideration. As a company committed to sustainability, we at Autojare look for materials that are not only effective but also environmentally friendly. This includes selecting materials that are recyclable and sourcing from suppliers that adhere to sustainable practices.

Sustainability in material selection ensures that we are minimizing our environmental footprint while delivering high-quality products to our customers.

Conclusion

In the world of L-Jaw Couplings, the choice of material is as crucial as any other design aspect. At Autojare, we pride ourselves on selecting the best materials for the job, ensuring that our products meet the high standards expected by our clients in the USA, Mexico, Canada, Europe, and Australia. Through careful material selection, we provide couplings that are durable, efficient, and environmentally sound.

| Product Model | Size (Outer Diameter mm) | Bore Diameter (mm) | NBR Model | Material | Weight (kg) | Torque Capacity (Nm) | Product Link |

|---|---|---|---|---|---|---|---|

| L075 | 45 | 12 | NBR-75 | HT250 Steel | 0.5 | 100 | Product Link |

| L090 | 58 | 15 | NBR-90 | HT250 Steel | 0.7 | 150 | Product Link |

| L095 | 65 | 18 | NBR-95 | HT250 Steel | 0.9 | 200 | Product Link |