As the CEO of Autojare, a China-based brand that prides itself on manufacturing premium L-Jaw Coupling Sets for a B2C market, I’ve encountered numerous questions regarding our products. One of the most common inquiries is about the sizes of L-Jaw Coupling Sets we offer. It’s crucial for our clients, ranging from brand chains and online retailers to large supermarket buyers across the USA, Mexico, Canada, Europe, Australia, and more, to find the perfect fit for their specific needs.

Understanding the needs of our diverse clientele, Autojare offers a wide range of L-Jaw Coupling Sets designed to meet various industrial applications. Our sizes range from small, medium to large, accommodating different torque and shaft diameters. This versatility ensures that no matter your machinery’s requirements, we have the right coupling set for you.

In our commitment to meet and exceed customer expectations, we continuously work with our factories to ensure high-quality production. Our L-Jaw Coupling Sets are not just about variety; they’re about providing solutions that are both reliable and efficient. The importance of choosing the right size cannot be overstated, as it directly impacts the performance and longevity of your machinery.

Why Is Choosing the Correct Size Important?

Choosing the correct size of L-Jaw Coupling Set is essential for ensuring optimal performance and preventing equipment failure. Incorrect sizing can lead to increased wear and tear, reduced efficiency, and even catastrophic breakdowns. This is why we emphasize the importance of accurate selection based on torque requirements and shaft diameter.

How Do I Determine the Right Size for My Application?

Determining the right size for your application involves understanding the torque requirements of your machinery and the diameter of the shafts being connected. At Autojare, we offer detailed specifications and technical support to assist in this process. Our product catalogs and technical guides provide comprehensive information to help you make an informed decision.

What Are the Common Sizes and Models Available?

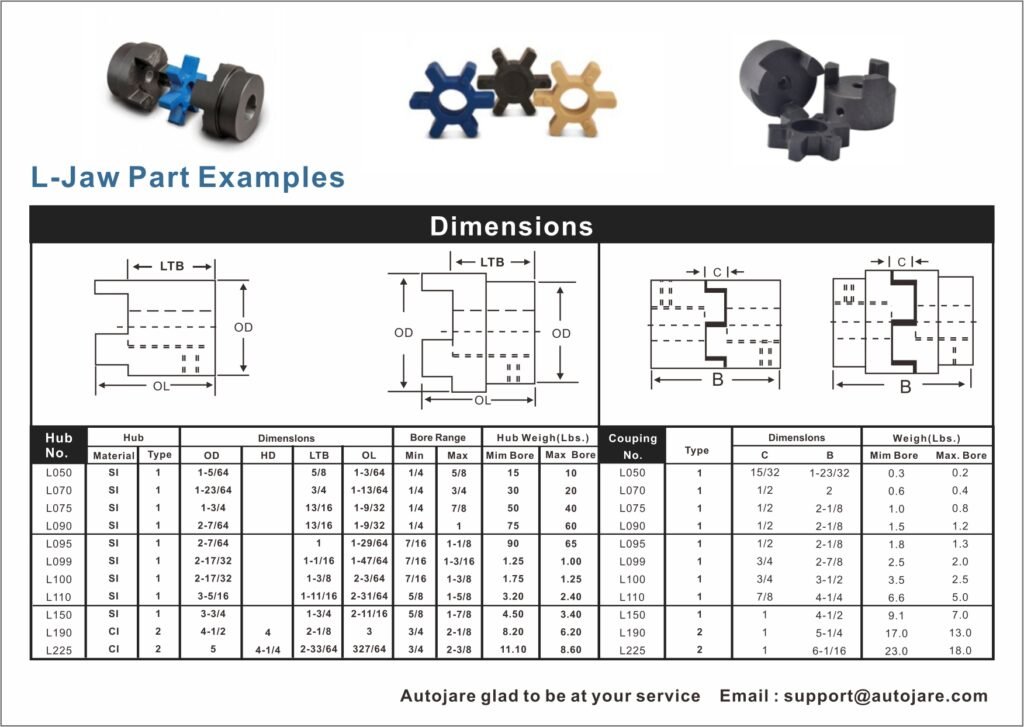

At Autojare, our L-Jaw Coupling Sets come in a variety of sizes to accommodate a wide range of industrial applications. To help you better understand the options available, we’ve summarized our most common sizes and their specifications in the table below. This format allows us to provide clear, concise information that’s easy to reference at a glance.

| Size Code | Nominal Torque (Nm) | Max Shaft Diameter (mm) | Outside Diameter (mm) | Length (mm) |

|---|---|---|---|---|

| L035 | 11.3 | 16 | 23.8 | 35.5 |

| L050 | 24.5 | 19 | 28.6 | 44.5 |

| L070 | 68.6 | 24 | 35.5 | 50.8 |

| L075 | 95.4 | 28 | 38.1 | 57.2 |

| L090 | 158.3 | 35 | 46.0 | 66.0 |

| L095 | 214.9 | 38 | 48.0 | 74.5 |

| L099 | 271.2 | 42 | 53.8 | 80.0 |

| L100 | 311.5 | 48 | 60.3 | 85.5 |

This table showcases L-Jaw Coupling Set sizes from the smallest, L035, suitable for light applications, up to the L100, designed for more demanding, heavy-duty operations. The nominal torque, shaft diameter, outside diameter, and length are key dimensions that affect the coupling’s compatibility and performance with your machinery.

By providing these details in a structured format, we aim to make it easier for you to identify the best coupling set for your specific requirements. Remember, selecting the right size ensures optimal performance, efficiency, and longevity of your equipment.

Spotlight on Key L-Jaw Coupling Sets: L075, L090, L095

In the diverse range of L-Jaw Coupling Sets we offer at Autojare, the L075, L090, and L095 models stand out for their robust performance and versatility across various applications. These models are designed to cater to a broad spectrum of industrial needs, offering superior durability and flexibility. Below, I delve into the specifics of each model to help you understand why they might be the perfect fit for your machinery.

L075 L-Jaw Coupling Set

The L075 model is a mid-range option that strikes an excellent balance between size and torque capacity. It’s designed for applications requiring a moderate level of power transmission without sacrificing space or efficiency.

- Nominal Torque: 95.4 Nm, making it suitable for applications such as medium-sized pumps, conveyors, and fans.

- Max Shaft Diameter: 28 mm, accommodating a wide range of shaft sizes for versatility in application.

- Dimensions: With an outside diameter of 38.1 mm and a length of 57.2 mm, the L075 provides a compact solution that doesn’t compromise on power.

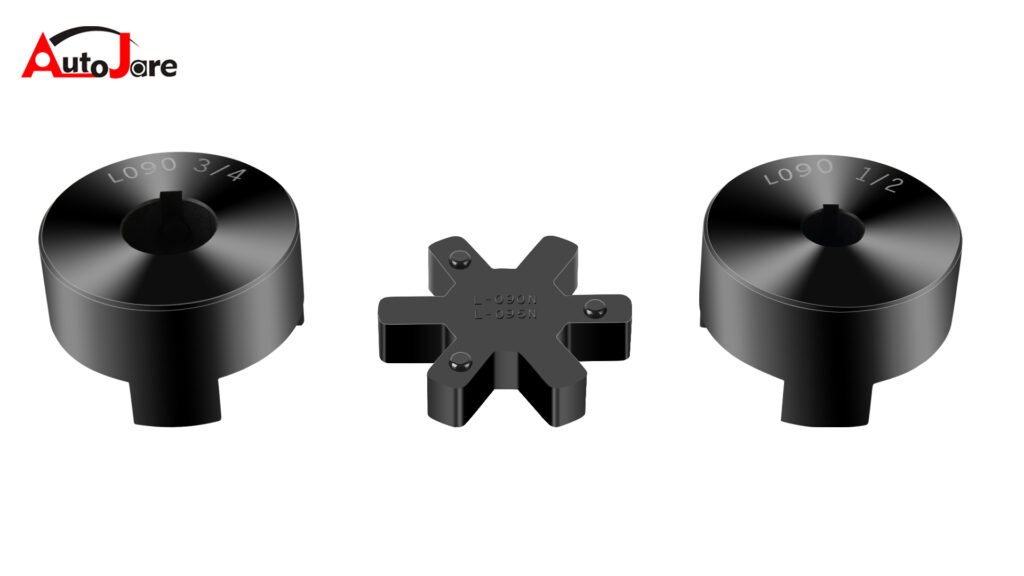

L090 L-Jaw Coupling Set

The L090 steps up in size and strength, designed to handle higher torque applications while still maintaining the adaptability Autojare couplings are known for.

- Nominal Torque: 158.3 Nm, perfect for heavier-duty applications such as industrial machinery and larger conveyor systems.

- Max Shaft Diameter: 35 mm, this model can accommodate larger shafts, making it ideal for a broader range of industrial machinery.

- Dimensions: The outside diameter of 46.0 mm and length of 66.0 mm provide a robust profile for demanding applications without excessive bulk.

L095 L-Jaw Coupling Set

The L095 model represents one of the higher capacity options in our range, designed for the most demanding applications where maximum torque and durability are critical.

- Nominal Torque: 214.9 Nm, it’s well-suited for heavy industrial applications, including large compressors, generators, and heavy-duty pumps.

- Max Shaft Diameter: 38 mm, ensuring compatibility with a wide variety of machinery and offering a high degree of flexibility for industrial setups.

- Dimensions: With an outside diameter of 48.0 mm and a length of 74.5 mm, the L095 combines high torque capacity with a relatively compact design, making it an excellent choice for space-constrained environments.

Why Choose L075, L090, or L095?

Choosing between these models comes down to the specific requirements of your application, including torque needs, shaft sizes, and space constraints. Each model is engineered with the highest standards of quality and durability, ensuring they meet the rigorous demands of industrial applications. Their versatility, combined with Autojare’s commitment to excellence, makes them a top choice for engineers and maintenance professionals seeking reliable, high-performance coupling solutions.

By providing detailed insights into the L075, L090, and L095 L-Jaw Coupling Sets, we aim to empower you with the information needed to make the best decision for your machinery. Remember, our team at Autojare is always ready to assist with any questions or specialized needs you may have, ensuring you find the perfect coupling solution for your application.

Why Autojare?

At Autojare, we stand out from our competitors through our unwavering commitment to quality, fast shipping times, and close cooperation with our factories. We understand the critical role that L-Jaw Coupling Sets play in the operational efficiency of your machinery. That’s why we go the extra mile to ensure our products meet the highest standards of reliability and performance.

Conclusion

Choosing the right size of L-Jaw Coupling Set is a critical decision that can significantly impact the efficiency and longevity of your machinery. At Autojare, we’re here to assist you every step of the way, from selection to installation. Our wide range of sizes and our commitment to quality make us the go-to source for your coupling needs.

That’s it! I hope this post has been informative and helpful in addressing one of the key questions about our L-Jaw Coupling Sets. Feel free to reach out to us for more information or assistance.